Blackfabric - Fiber reinforced composites

In 2018, Texifre S.L. and Marina Textil S.L. decided to start a new project together, investing in equipment, facilities and human resources to create a new line of fiber-reinforced thermoplastic fabrics for composites world.

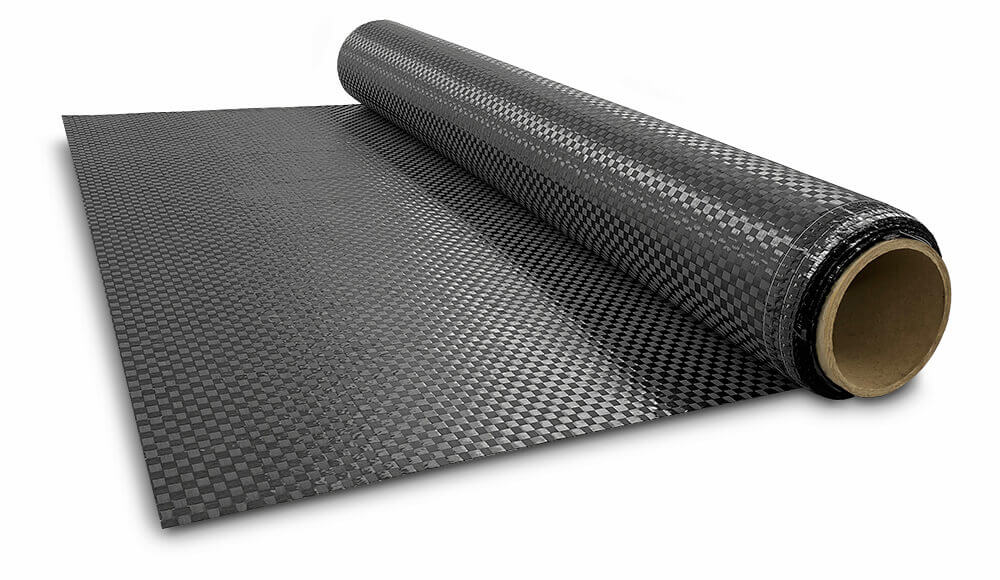

Under the name of Blackfabric, developing bidirectional composite fabrics made of fibers (responsible of mechanical properties) and a thermoplastic matrix that wraps and binds the fibers (responsible of physical and chemical properties), widely known as “fibre reinforced thermoplastic composites”. Blackfabric was born due to the increasing need for a more affordable and sustainable textile solutions in the field of advanced composite materials. Using the know-how on design and production of technical fabrics expertise, Blackfabric's main objective is to bring innovative and sustainable solutions to the market.

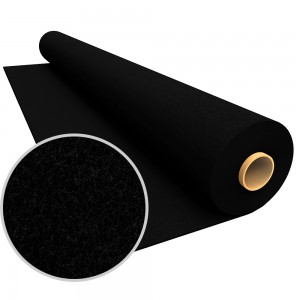

Working with a huge variety of reinforcing fibers like carbon fibers, glass, basalt, aramid, naturals fibers and even recycled carbon fibers. Combined with thermoplastic polymers such as polyamide 6, polyamide 12, polycarbonate among others. Developing a thermoplastic prepregs collection, which already incorporate the right amount of fiber-matrix necessary for the subsequent thermoforming process.

In contrast with current composites made from thermoset resins, thermoplastic polymers can be moulded several times by reaching its melting temperature. This property can be repeated without modifying their mechanical properties, which allows the parts to be repaired, extending their useful life. Finally, it allows the pieces to be recycled, separating the matrix from the fibers with chemical separation processes or a pyrolysis process.

Other advantages of working with thermoplastic matrices is that they allow faster manufacturing processes, with a high production rate and repeatability. These can be stored and transported at room temperature, which means significant energy savings, and they are easy to handle and cut.

.jpg)

Texfire has a new production plant, equipped with state-of-the-art machinery to weave all types of fibers and even flat tapes up to 20mm wide. The lamination plant is used to apply thermoplastic polymers, producing "prepregs" compounds and also to stabilize all types of fabrics, facilitating the cutting and shaping process, without deforming the structure of the fabric.

The consolidation process of thermoplastic compounds consists of adding heat and pressure, through a thermoforming process. Texfire has a hot press for the validation and quality control of the fabrics, and the analysis of the final result of the compound. It is also used for the manufacture of prototypes and small series of new products.

.jpg)

.jpg)

.jpg)

Thanks to the support of the ACCIÓ project of the Generalitat de Catalunya, together with the Eurecat technology centre, it has been possible to develop a sensorized mold, which incorporates sensors to obtain precise control of the temperature and pressure of the thermoforming process for the manufacture of standardized "organosheet" plates, for the performance of mechanical tests of the materials. The sensorized mold allows in situ quality control during the manufacture of characterization plates and, in addition, allows advanced studies to optimize the consolidation process for each given material.

.png)

.jpg)

.jpg)