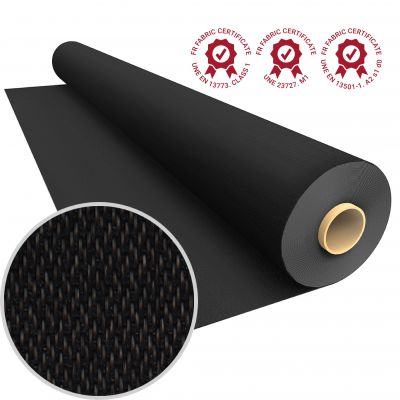

FR WELDING FABRIC WELS2

REVERSIBLE FABRIC FOR WELDING

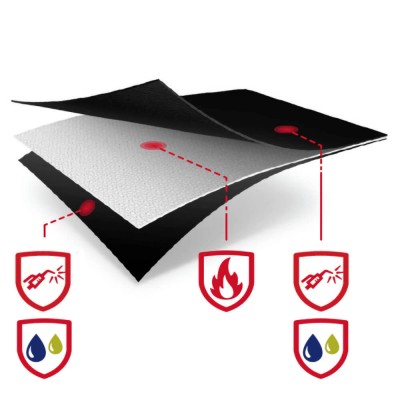

WELS2 is a flame retardant fabric for welding, designed and manufactured by Texfire. Resists continuous temperatures of 300ºC and peak temperatures of 900ºC. It is a fabric composed by fiberglass, which adds mechanical resistance and flexibility, with a silicone coating for high temperatures in both sides that repels sparks and melted metal projections. Thus, WRLS2 fabric is completely impermeable to liquids and fumes, and can be used on both sides.

WELS2 welding fabric has been developed in order to protect before welding sparks (TIG, MIG, Electrode...) cutting and grinding. It is a versatile fabric that can be used to delimit areas, as a curtain way, or to protect surfaces or objects, even from melted metal projections and splashed. Texfire recommends its use on a diagonal or vertical position. With a weight not higher than 600gsm, it is a very flexible and pliable fabric, easy to cut and handle because it does not “fray.” Besides its fire resistant features, WELS2 fabric is totally impermeable to liquids and fumes. Thus, it offers the same level of protection in both sides, which allows it to protect and work in 2 areas simultaneously.

The WELS2 obtains EN ISO 13501-1 certification in 2023 - Classification of the fire performance of construction products and building elements - achieving results A2 s1 d0. Additionally, it is certified in 2020 according to UNE 23727 standards - Reaction to fire of construction materials - with an M1 classification. Furthermore, it is certified according to UNE 13773 standards - Fire behavior of curtains and drapes - with a Class 1 classification. Moreover, it surpasses the EN ISO 9150 standard - Behavior of materials subjected to small splashes of molten metal - with a Class 1 classification.

FEATURES

- Resists continuous temperatures of 300ºC and peak temperatures of 900ºC.

- Fabric’s width 0,5 mm, weight 590g/m2 and useful wideness of 150 cm.

- Can be used on both sides.

- Repels the impacts of incandescent metal splashes and other materials.

- Totally impermeable to water, oils, acids and fumes.

- Flexible fabric, easy to handle, does not fray being cut with scissors.

- Suitable for indoors and outdoors use.

- Completely opaque, suitable to protect sensible elements.

- Its fire resistant features are permanent, not decreasing over time. Does not expire.

Data sheet

- Fire resistance

- UNE 23727 | M1

UNE EN 13773 | CLASS 1

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C1

- Traction resistance

- EN 13934-1 | Warp 2700 NT Weft 1700 NT

- Flame propagation

- ISO 15025 | A1 - A2

- Water penetration resistance

- EN 20811 | > 100.000 Pa

- Resistance welding and cutting projections

- EN 9150 | CLASS 1

- Heat resistance

- ISO 17493 | PASS

- Fire behavior

- EN ISO 13501-1 | A2 - s1 - d0

APPLICATIONS.

- Flame retardant fabric for welding.

- Flexible flame retardant barrier.

- Opaque flame retardant curtain.

- Fire blanket for welding.

- Contention barrier from fumes and liquids.

- Especially suitable to manufacture flame retardant covers or spreads.

SECTORS.

- TIG, MIG and ELECTRODE welding.

- Radial cutting and grinding.

- Naval sector, Offshore and subcontractors.

- Construction sector.

- Foundries and metal industries.

- Any application where a flame retardant protective and flexible fabric is required.

USE RECOMMENDATIONS.

- Always use it placed as vertically as possible.

- Can be used on both sides.

- Can be washed using a wet cloth.

- Do not use alcohols, solvents or detergents to wash (flammable leftovers can be left).

- It is recommended always to store it in rolled position as a tube in order to enhance its useful life.