CUSTOM-MADE FLAME RETARDANT WELDING BLANKET

CUSTOM-MADE WELDING BLANKETS FOR WELDING, CUTTING, AND GRINDING.

Texfire offers the possibility of custom-made blankets for the protection of equipment, objects, or installations against sparks and/or incandescent projections that occur during welding, cutting, and grinding work. These flame retardant welding blankets can be made based on the customer's needs and with different fire-resistant fabrics depending on the type of welding to be performed.

Texfire's custom-made welding blankets are made with meta-aramid fire resistant thread. The perimeter is reinforced with a bias tape, and Texfire also offers the option of adding metal eyelets every 50 cm to facilitate attachment.

The maximum measurements that can be acquired are 7,5x10 meters. For higher sizes, we recommend our clients contact Texfire’s team via phone or email.

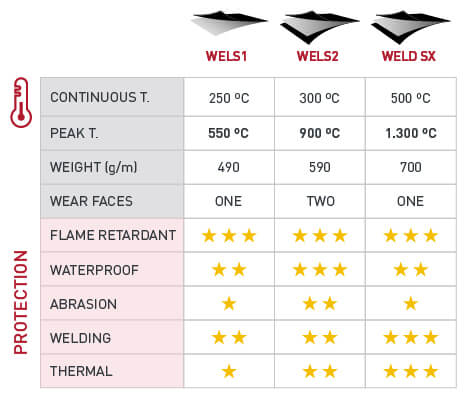

SEE WELDING FABRICS COMPARATIVE TABLE

Fabrics we can use to tailor the blankets are Texfire’s exclusive and confer different features to each blanket:

Weld S1 blanket: Tailored in WELS1 flame retardant fabric, it is a fibreglass blanket with a side covered with a special silicone for high temperatures that avoids incandescent particles to get stuck in the blanket, increasing its lifespan. This welding blanket is light, flexible and waterproof, and it resists temperatures of 250ºC in continuous works and work peaks up to 550ºC. It is recommended to use it vertically or diagonally.

Weld S2 blanket: Made with WELS2 flame retardant fabric, it provides maximum safety and protection against sparks and metal splashes. It features a silicone coating on both sides, preventing splashes from sticking, meaning it can be used on either side. It withstands continuous working temperatures of 300ºC and peak temperatures up to 900ºC. Additionally, this blanket is completely impermeable to liquids, grease, and oils, making it easy to clean with a damp cloth. It is recommended for use in a vertical or diagonal position.

Weld SX blanket: Tailored in WELD SX fabric, it is the only welding blanket that achieves containing incandescent sparks, at the same time it performs as a thermal barrier. It brings protection in front of practically all kinds of welding techniques: MIG, Electrode, TIG, spot welding, etc. It is also useful for cutting operations: Radial cutting, oxyfuel, plasma cutting and grinding… WELD SX welding blanket has a silicone finish on one side and a Preox fabric on the other that performs as a thermal barrier, avoiding heat transference at its most. It resists continuous working temperatures of 500ºC and thermal peaks up to 1300ºC. It is the only blanket in the marketplace performing as a thermal insulator, same time as containing incandescent projections.

These fabrics meet the following regulations:

The WELS1 fabric is certified under the UNE 23727 regulation - Assessing fire reaction of construction materials - obtaining an M1 classification.

The WELS2 fabric is certified under the UNE 23727 regulation - Assessing fire reaction of construction materials - with an M1 classification. Additionally, it complies with the UNE 13773 regulation - Evaluating the fire behavior of curtains and draperies - achieving a Class 1 rating. It also surpasses the EN ISO 13501-1 standard - Classifying fire behavior of construction products and building elements - with A2 s1 d0 results.

The WELD SX fabric is certified under the EN ISO 13501-1 standard - Classifying fire behavior of construction products and building elements - achieving B s1 d0 results. It also complies with the UNE 23727 regulation - Assessing fire reaction of construction materials - with an M2 classification.

APPLICATIONS.

- Fire retardant blanket for MIG welding.

- Fire retardant blanket for TIG welding.

- Fire retardant blanket for Electrode welding.

- Fire retardant blanket for radial cutting.

- Flame retardant blanket for oxyfuel cutting works.

- Flame retardant blanket for plasma cutting works.

- Flame retardant blanket for grinding.

- Flame retardant blanket for soft soldering.

SECTORS.

- Automotive.

- Naval sector and shipyards.

- Construction sector and subcontractors.

- Foundries, metalworking and steel companies.

- Mechanical workshops.

- Machinery manufactories.

- Boiler-making.

- Petrochemical and pharmaceutical sectors.

USE RECOMMENDATIONS.

- Welding workshops.

- Always use the shiny side exposed to the Sparks. (Weld S1 and Weld SX).

- It can be washed with a wet cloth.

- Never use alcohol, solvents, or detergents to wash it.

- Do not rub, brush or vacuum the plush side (Weld SX).

- The longer the distance to the spark source, the better the fabric will behave.

- It is recommended to store it alwaysrolled with the elastic band, to raise its lifespan.