CUSTOM-MADE CURTAIN FOR WELDING

CUSTOM-MADE FLAME RETARDANT CURTAIN FOR WELDING WORKS

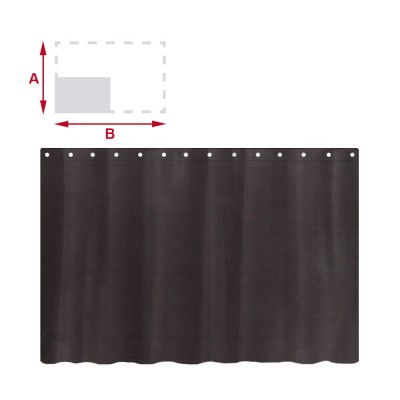

Texfire’s flame retardant curtains for welding can be tailored up to measure according to our client’s needs. The maximum sizes for each curtain are 7,5x10 meters.

These curtains are tailored with WELS2 fabric. It is a flame retardant fabric made of fibreglass which brings mechanical resistance and flexibility, with a special silicone coating for high temperatures on both sides that repel sparks and projections coming from welding, curing and grinding operations. These welding curtains resist continuous temperatures of 300ºC and peak temperatures of 900ºC. Sews are also made with meta-aramid fire resistant thread.

Texfire’s custom-made welding curtains have a reinforcement fold in all the perimeter that avoids tearing and incorporate grommets every 25 cm in the upper edge to ensure a stable holding. These curtains are completely opaque and waterproof before liquids and fumes, they can be used on both sides. Suitable to all kinds of welding (TIG, MIG, Electrode…) and cutting operations (radial, oxyfuel or plasma cutting). They are suitable to separate, define and ensure working areas, these curtains are flexible, light, and easy to clean with a wet cloth. They can be used in internal installations and outdoors.

WELS2 flame retardant fabric is certified in 2020 with regulation UNE 23727 - Reaction to fire of building materials - with an M1 classification. And according to regulation UNE 13773 - Behaviour in front of the fire in curtains and drapery -, with a Class 1 classification. It also meets regulation EN ISO 9150 - Behaviour of materials before the impact of small melted metal splashes, with a Class 1 classification

FEATURES

- Resists continuous temperatures of 300ºC and peak temperatures of 900ºC.

- Fabric’s thickness 0.5 mm, weight 590 g/m2.

- Suitable to protect regarding all kinds of welding.

- Protection against projections derived from radial cutting or oxyfuel cutting.

- Suitable to sectorize spaces or delimit working areas.

- Effective on both sizes.

- Suitable for both indoor and outdoor use.

- Waterproof in front of water, oils, greases, fumes, and vapours.

- Asbestos-free and other cancerous agents.

- Totally opaque.

- Its fire resistant features are permanent, not decreasing with use.

- Grommets every 25 cm in the upper edge.

Data sheet

- Fire resistance

- UNE 23727 | M1

UNE EN 13773 | CLASS 1

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C1

- Traction resistance

- EN 13934-1 | Warp 2700 N ± 10% Weft 1700 N ± 10%

- Flame propagation

- ISO 15025 | A1-A2

- Water penetration resistance

- EN 20811 | 100

- Resistance welding and cutting projections

- EN 9150 | CLASS 1

- Heat resistance

- ISO 17493 | PASS

SECTORS.

- Welding workshops.

- Automotive.

- Naval sector and shipyards.

- Construction sector and subcontractors.

- Foundries, metalwork and steel industries.

- Mechanical workshops.