FR FABRIC FOR WELDING WELS1

FLAME RETARDANT FABRIC FOR WELDING.

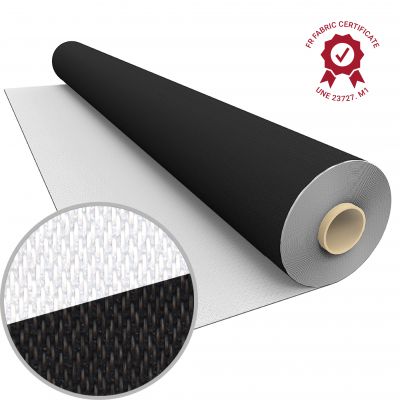

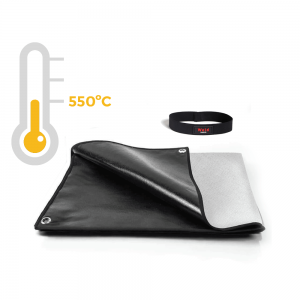

Texfire’s welding WELS1 fabric is an E-Glass fiberglass fabric with a black silicone coating for high temperatures on one of its sides. The fiberglass base brings mechanical resistance. The black silicone coating repels sparks and sphashes coming from welding works and also turns it into a fabric impermeable to any kind of liquids, gases and fumes. Its fire resistant features are permanent and it withstands temperatures of 250ºC in continuous works and 550ºC in peak works.

WELS1 has been designed to protect objects, surfaces or areas before incandescent sparks derived from processes of light welding, cutting and grinding. It is recommended to use it vertically, as a curtain type, always placing the silicone side on the exposed area. Thanks to its flexibility and lightness (<500 gsm) this fabric adapts perfectly over any surface that is wanted to protect, for example over metallic structures, boilermaking installations, pipes, etc.

WELS1 is a very versatile fabric that can be used as a flame retardant cover, as a curtain or as a welding blanket. The silicone side improves the fabric’s stability, easing its handling and cutting, without tearing nor spreading threads. WELS1 fabric resists abrasion better than a fiberglass fabric without coating, offering also a good balance between quality-performance-price.

WELS1 flame retardant fabric is certified in year 2020 with regulation UNE 23727 - Reaction to fire of construction materials -, with M1 classification. It also meets regulation EN ISO 9150 with a Class 1 classification - Behavior of materials over the impact of small melted metal splashes -, a test performed in an internal laboratory.

FEATURES.

- Resists continuous temperatures of 250ºC and peak temperatures of 550ºC.

- Fabric’s thickness 0,4mm, 490 g/m2 and useful width of 150 cm.

- Repels projections and melted metal splashes.

- Totally impermeable to liquids and fumes.

- Flexible fabric, easy to handle, does not tear when being cut.

- Suitable for indoor and outdoor use.

- Opaque, suitable to protect elements sensible to light.

- Its permanent fire resistant features don’t decrease with use. Does not expire.

Data sheet

- Fire resistance

- UNE 23727 | M1

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C1

- Traction resistance

- EN 13934-1 | Warp 2700 NT Weft 1700 NT

- Flame propagation

- ISO 15025 | A1 - A2

- Water penetration resistance

- EN 20811 | > 100 Pa

- Resistance welding and cutting projections

- EN 9150 | CLASS 1

- Heat resistance

- ISO 17493 | PASS

APPLICATIONS.

- Flame retardant cover.

- Smoke barrier.

- Fire blanket for welding.

- Flame retardant curtain for welding.

- Flame retardant fabric, light and flexible to protect objects or areas.

SECTORS.

- TIG, MIG and ELECTRODE welding.

- Construction sector.

- Foundries and metal industries.

- Welding workshops.

- Naval sector, Offshore and subcontractors.

- Mechanical workshops.

- Installation and maintenance companies.

USE RECOMMENDATIONS.

- Use on the shiny face being exposed to sparks.

- Vertical and diagonal use.

- Can be washed with a wet cloth.

- Do not use alcohols, solvents or detergents to wash, becauses flammable leftovers can remain.

- Do not rub, brush or vacuum.

- As higher the distance from the sparks source to the fabric, the better it will behave.

- It is recommended always to be stored in a rolled position as a tube in order to enhance its useful life.