Showing 1-8 of 8 item(s)

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Cookie preferences

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | texfire.net | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | texfire.net | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |

Texfire manufactures and markets technical fabrics for high temperatures and all kinds of textile solutions.

Custom tailoring with technical fabrics that offers multiple advantages compared to other systems or materials.

Texfire offers 2 lines of technical manufacturing, optimizing fabric usage and production times, to provide customized solutions regardless of the required volume.

Textile thermal insulation increases thermal efficiency of gas or liquid circuits, simultaneously reducing its’ energy consumption.

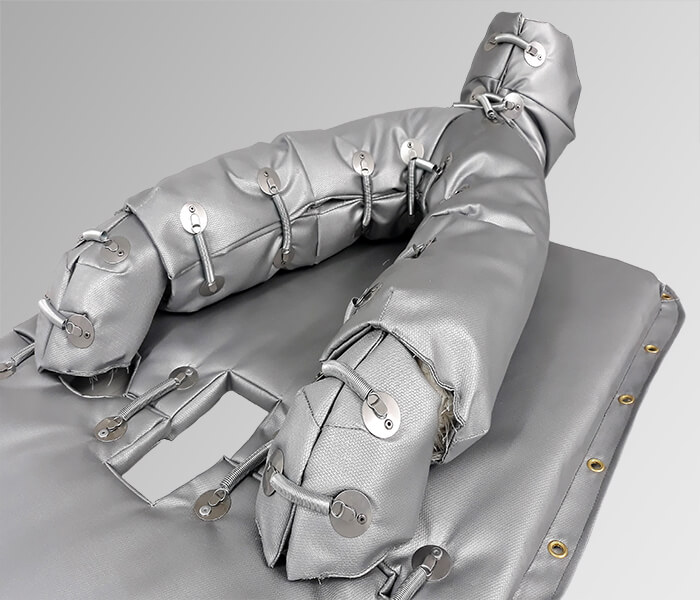

Design and custom manufacturing of covers or protectors, tailored to meet various thermal or mechanical needs.

Texfire offers the possibility to purchase the fabrics and components necessary for you to manufacture or repair your own textile lagging.

Flame-retardant technical fabrics designed to meet various thermal and mechanical needs in the industrial sector.

Fire-resistant components for sewing, securing, and fixing lagging fabrics or other multi-layered compositions.

We manufacture our own flame-retardant fabrics and tailored solutions for industrial use based on the technical requirements of each project: thermal barriers, textile expansion joints, compensation bands, thermal insulation blankets, fire-resistant covers, etc.

THERMAL SHIELD FOR DRONES

Aluminized flame-retardant fabric ALTOX 450, lightweight, with a resistance of up to 1,300ºC

_1.jpg)

INSULATING COVER FOR 1,000 L IBC TANK

Aluminized flame-retardant fabric ALTOX 450 that provides thermal insulation, flame protection, and acts as a thermal shield.

THERMAL COVERS FOR NAVAL COLLECTOR

Multilayer flame-retardant and thermal insulating composition with the ability to shield up to 290ºC.

Please sign in first.

Access