EXTREME TEMPERATURE SILICA P2 FABRIC

FLAME RETARDANT FABRIC FOR EXTREME TEMPERATURES WITH A POLYMERIC COATING

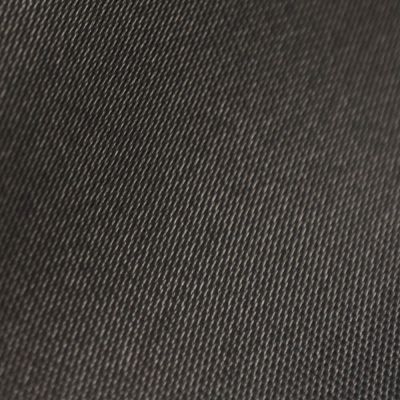

SILICA P2 fabric is a flame retardant fabric whose basis is made out of silica fibers. Another distinguishing feature of this fabric is that it incorporates a polymer coating it on both sides. Silica fibers resist extreme temperatures up to 1,100ºC in continuous works and 1,500º in working peaks. The coating adds a better resistance to abrasion and waterproofing to liquids, fumes, and gases.

SILICA P2 fabric has been designed and made to offer a good performance in very high temperatures, maintaining the resistance and the structural integrity continuously on environments up to 1,100ºC. Its features make that this fabric can be used to protect in front of special tasks in extreme temperature environments, with extreme heat sources or in contact with very hot pieces. In addition, it is a fabric that can be cut and be tailored without fraying, which allows it to be used to tailor covers or thermal blankets for controlled cooling processes of pieces. It has a good performance when being in contact with incandescent metal pieces.

The black polymer coating for high temperatures helps to improve the resistance to abrasion and friction of the fabric, and eases its confection and cutting, avoiding frays in the fabric. It is important to highlight that the polymeric coatings disappear when being exposed to temperatures higher than 300ºC.

This fabric has the official EN 13501-1 certification - Classification, based on fire behavior, of construction products and building elements - Achieving the A2-s1-d0 classification. It has also been tested in the internal laboratories of Texfire according to the UNE EN ISO 9151 standard for Determining heat transmission when exposed to a flame, with a result of B1. It has also undergone the EN ISO 15025 flame test, achieving an A1-A2 result. The polymeric coating of this fabric gives it excellent resistance to abrasion and wear, based on the EN 12947-2 test (abrasion resistance), considering that the fabric is made of silica fibers, which are thermally very resistant but mechanically fragile by nature.

Determination of heat transmission when exposed to a flame resulted in B1. It was also subjected to the EN ISO 15025 flame test, achieving results A1-A2. The polymeric coating of this fabric provides excellent resistance to abrasion and friction, based on the EN 12947-2 test (abrasion resistance), considering that the fabric is made of silica fibers, which are naturally highly thermally resistant but mechanically fragile.

FEATURES

- It resists continuous temperatures up to 1.100ºC and peak temperatures of 1.500ºC.

- Fabric thickness 0.6 mm, 630 gr/m2 and useful width of 150 cm.

- Silica fibers don’t irritate skin. Does not itch.

- Fabric for high temperatures, it resists contact heat well.

- Reversible fabric (same features on both sides.)

- Permanent fire resistant, permanent features, does not expire.

Data sheet

- Fire resistance

- NON-COMBUSTIBLE

- Convective heat

- ISO 9151 | B1

- Fire behavior

- UNE EN 13501-1 | A2 - s1 - d0

APPLICATIONS

- Thermal blanket for controlled cooling processes.

- Protection blanket for complex welding.

- Flame retardant covers for extreme temperatures.

- Thermal mats.

- Expansion/compensation joints.

- Covers for engines.

- Coatings of parts or hot areas up to 1.100ºC.

SECTORS

- Foundries.

- Steel sector.

- Complex welding.

- Heavy machinery.

- Petrochemical.

- Boilermaking.

- Construction.

- Automotive.