ALUMINIZED FABRIC PARATEX 460 ALP

ALUMINIZED PARA-ARAMID FABRIC

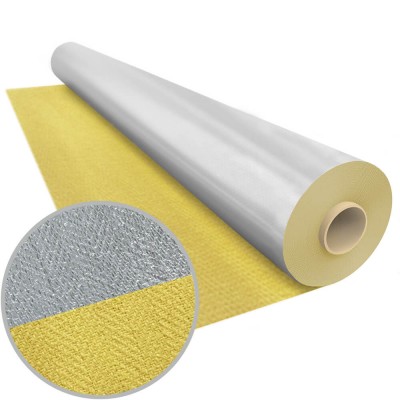

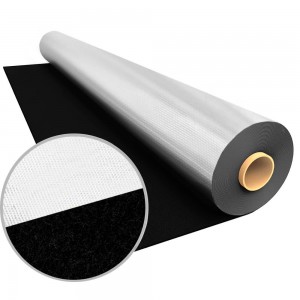

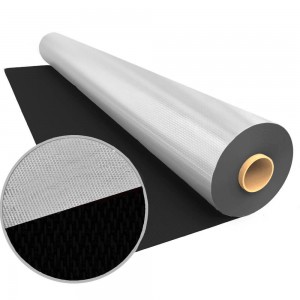

The fabric PARATEX 460 ALP is a para-aramid fabric with a special fabric ligament which brings flexibility and good drapability. This fabric is aluminized with a thin layer of aluminum powder, which avoid foil cracking and improve the durability of the fabric. Para-aramid fibers turn it into an inherent fire resistant fabric, with high mechanical resistance, resistance to abrasion, cutting and vibrations. It also offers a good performance in high temperatures situations (up to 400ºC). The aluminized side of the fabric performs as a thermal shield before radiant and convective heat sources, in addition to protecting the para-aramid fibers from UV beams.

Aluminized fabric PARATEX 460 ALP is mainly designed to be used where high mechanical resistance or abrasion values are required, exposed to radiant or convective heat sources at high temperatures. It is used for welding robot covers or in metal foundries, hose, pipes or cable covers. PARATEX 460 ALP offers a great resistance to abrasion and cuttings, which turns it into a suitable fabric for personal protection equipment (PPEs), like gloves, aprons, neck covers… It can bear temperatures up to 200ºC in continuous working, arriving up to 500ºC in working peaks. It has a width of 1,1 mm, but it keeps a great flexibility.

PARATEX 460 ALP has been tested in tests performed in Texfire’s internal laboratories, meeting regulation ISO 15025, resistance limited to flames.

FEATURES

- Withstands continuous temperatures of 200ºC and peaks of 400ºC.

- Fabric thickness 1,1 mm, 610 g/m2 and useful width of 150 cm.

- The aluminized face offers thermal insulation against radiant and convective heat sources.

- Easy handling, does not fray when cut with scissors.

- Flexible fabric, resistant to cycles of movement and rubbing.

- Its fire resistant properties are permanent, they do not diminish with use. Does not expire.

- High resistance to traction, abrasion and cutting.

- Good dimensional stability, does not shrink.

Data sheet

- Tearing resistance

- ISO 13937-2 | Warp 135 N Weft 90 N

- Convective heat

- ISO 9151 (ISO 11612) | B1

- Radiant heat

- ISO 6942 (ISO 11612) | C3

- Traction resistance

- EN 13934-1 | Warp 2220 N Weft 730 N

- Flame propagation

- ISO 15025 | A1

- Melted metal splashes

- ISO 9185 (ISO 11612) | D3 - E3

APPLICATIONS.

- Aluminized flame retardant drape.

- Contention barrier for fumes and liquids.

- Cases for robots of welding, and grinding or cutting operations.

- Protection screen for radiant heat sources.

- Personal protection equipments (gloves, neck protection…).

- Covers for hoses and cables.

SECTORS.

- Automotive.

- Foundries.

- Metal industries.

- Petrochemical industries.

USE RECOMMENDATIONS.

- Place the aluminized side exposed to the heat source.

- Avoid that the fabric’s internal side (the yellowish one) gets exposed to UV beams. Pararamid fibers are photosensitive.

- Can be washed using a wet cloth.

- Never use alcohols, solvents or detergents to wash it (flammable remains can remain).

- It is recommended to store it always rolled as a tube in order to extend its useful life.

- Avoid to expose the para-aramid fibers side to UV beams.