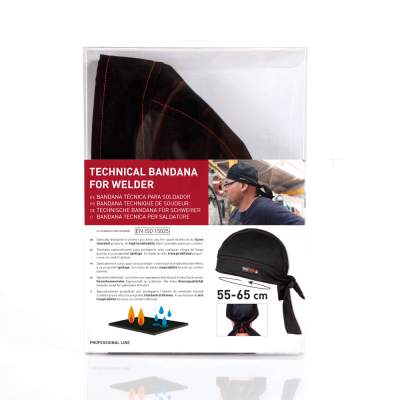

FLAME RETARDANT WELDING BANDANA

FLAME RETARDANT HEAD PROTECTION GARMENT EPI CAT II

The Texfire flame retardant bandana is designed to safeguard workers' heads against sparks, fire, or other incandescent projections occurring during tasks such as welding or cutting. It is compatible with the use of welding masks, covering the entire top of the head. This flame retardant garment is certified as Personal Protective Equipment (PPE) CAT II.

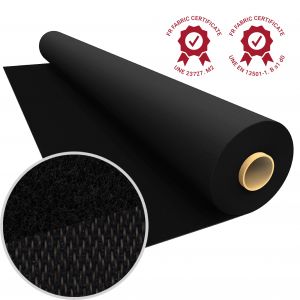

The fire resistantt properties of this bandana are inherent, meaning it retains this quality over time and is not affected by wear or washing. It can be laundered like any other conventional garment to eliminate bacteria or odors.

Weighing just 50 grams, this bandana is crafted from MARKO fabric in black. Its blend of cotton with flame retardant fibers provides a soft and pleasant touch, offering a high level of comfort and breathability to the wearer. As for its dimensions, it is one size fits all, with a total perimeter of 55-65 cm and can be easily adjusted to the head using its rear ties.

The Texfire flame retardant bandana is made with a multinorm inherent flame retardant fabric. This protective garment is certified as CAT II PPE and bears the European CE marking. It complies with the standard EN ISO 14116 - Protective clothing against flame and limited flame spread and also with the standard EN ISO 13688 – General requirements for protective clothing.

FEATURES

- One size fits all. Head circumference 55-65 cm.

- Very lightweight, only 50 g.

- CAT II PPE certification, with European CE marking.

- Inherent Flame Retardant Fabric. Permanent properties.

- Machine washable without diminishing its properties.

- Prevents bacteria and odors.

- Breathable and comfortable.

- Easy to put on and adjust.

Data sheet

- Tearing resistance

- EN 13937-2 | Warp 30 N (-5 N) Weft 30 N (-5 N)

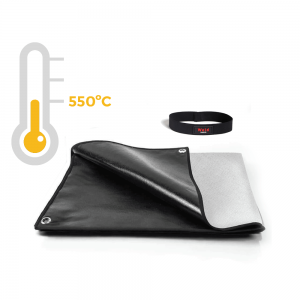

- Fire resistance

- ASTM D6413 | PASS

- Dimmensional stability

- EN ISO 5077 | Warp 3% Weft 3%

- Traction resistance

- EN 13934-1 | Warp 770 N ± 10% Weft 550 N ± 10%

- Welding and related techniques

- EN 11611 | CLASS 1

- Electrical arch

- EN 61482-1-2 | CLASS 1

- Abrasion Resistance

- EN 12947-2 | 25.000 rev

- Antiestatic

- EN-1149-3 | PASS

- Water Vapor Resistance

- EN 31092 | Ret: 3,6066 m² Pa/W

- Thermal Resistance

- EN 31092 | Rct: 0,200 m² K/W

- Pilling Resistance

- EN 12945-2 | 5.000 CYCLES

APPLICATIONS.

- Flame retardant bandana for welding works, TIG, MIG/MAG and SMAW.

- Flame retardant head protector to avoid incandescent projections from cutting or grinding operations.

SECTORS.

- Welding and cutting.

- Mechanical workshops.

- Naval.

- Renewable energy.

- Electric Companies.

- Petrochemical companies.

- Railway.