TEXTILE LAGGING

FOR VALVES AND FLANGES

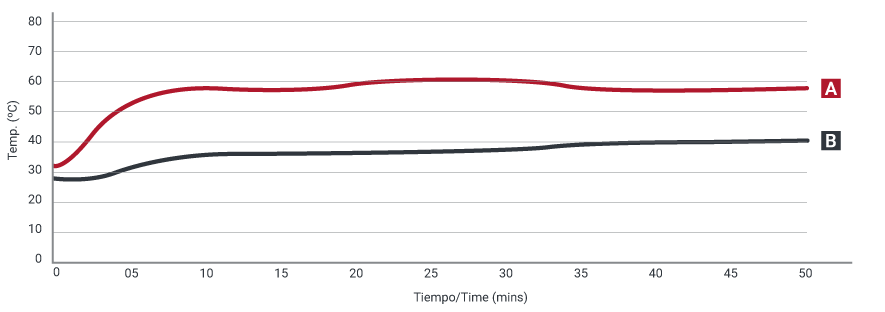

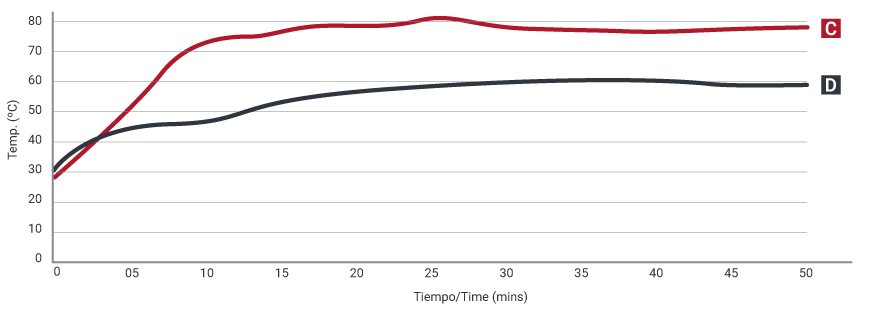

Texfire's thermal insulation jackets are a multi-layered textile solution used to prevent thermal leaks from the circuit. These heat losses compromise the process stability and lead to an increase in energy consumption, to maintain the temperature of the liquids or gases being transported.