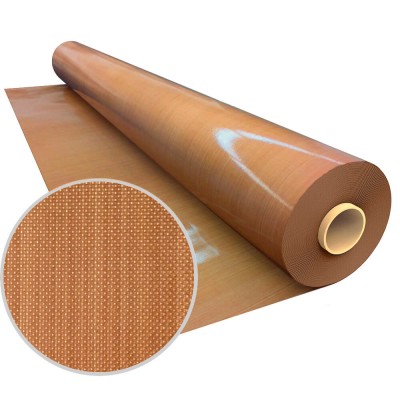

ANTI-ADHERENT FABRIC EGLA 100 PTFE

FLAME RETARDANT ANTI-ADHERENT AND ANTI-ACID FABRIC

Flame retardant fabric EGLA 100 PTFE is composed of a fiberglass of 110g/m2, with a coating of 70gr. Made of polytetrafluoroethylene (PTFE) on both sides. Its fiberglass nucleus confers mechanical resistance and dimensional stability to the fabric. The PTFE coating turns it into a reversible fabric that can be used indistinctly on both sides, totally impermeable to liquids and fumes, with a great chemical resistance to many acids and corrosive liquids. The plain and shiny surface of PTFE turns it into an anti-adherent fabric, able to repel any kind of substance and material. It also offers good behaviour before high temperatures, being able to resist up to 260ºC in continuous working.

EGLA 100 PTFE fabric has been designed for applications where anti-adherence features are required, like in conveyor belts or conveyors. It is also used as a barrier for gases, fumes or vapours in compensation strips or expansion joints in smoke circuits of cement industries. Thanks to its resistance up to 260ºC continuous working, it is also used as a separating agent in thermoforming processes of pieces, or in lamination and production processes in textile industries.

EGLA 100 PTFE has been tested in mechanical tests performed in Texfire’s internal laboratories, with regulation ISO 15025 - Protection against flames. Test method for limited flame spreading.- with an A1-A2 result. In addition, it has been tested with regulation EN 13934-1 - Features of fabrics before traction. Maximum strength determination and lengthening to the maximum strength by strap method. - With a warp classification of 1450 NT and weft classification of 1300 NT.

FEATURES

- Fabric’s thickness 0,13 mm, grammage 250 g/m² ±5% and useful width of 100 cm.

- It resists temperatures up to 260ºC.

- Antiadherent slipping surface.

- Permanent fire resistant, does not spread flames.

- Impermeable to liquids, gases and fumes.

- Minimum thermal expansion.

- Great dimensional stability.

- Reversible, same features on both sides.

- Thermowelded.

Data sheet

- Tearing resistance

- EN 13537/2 | Warp 20 NT Weft 18 NT

- Traction resistance

- EN 13934-1 | Warp 1450 NT Weft 1300 NT

- Flame propagation

- ISO 15025 | A1 - A2

- Humidity absorption

- 0,005%

APPLICATIONS.

- Conveyor belts.

- Main blades.

- Anti-friction surfaces.

- Strips for shrink tunnels.

- Expansion joints.

- Cases.

- Chemical insulators.

- Laggings.

SECTORS.

- Food sector.

- Textile.

- Composites.

- Lamination.

- Construction.

- Cement industries.

- Installation companies.

- Maintenance companies.

- Petrochemical industries.

- Boilermaking industries.

USE RECOMMENDATIONS.

- Can be cleaned easily with a wet cloth.

- Exercise caution if charged with static power, in order to avoid electrical shocks.

- It is recommended to store it always rolled as a tube in order to enhance its useful life.

- Never use alcohol, solvents or detergents to wash it (flammable remains can remain).