ALUMINIZED FR FABRIC WELS1 ALP

FLAME RETARDANT ALUMINIZED FABRIC THERMAL BARRIER

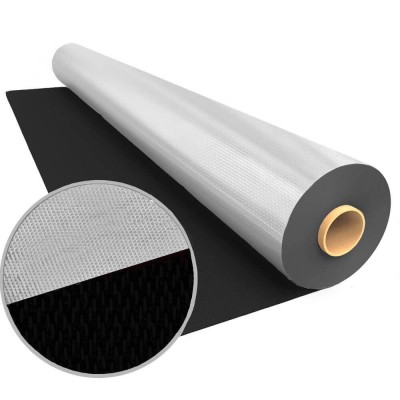

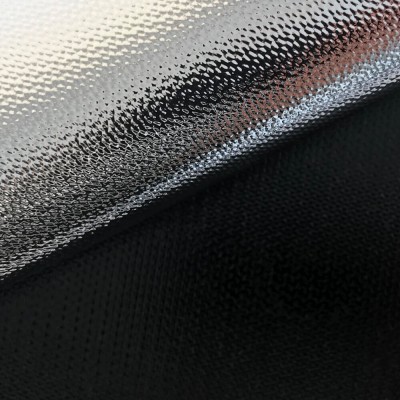

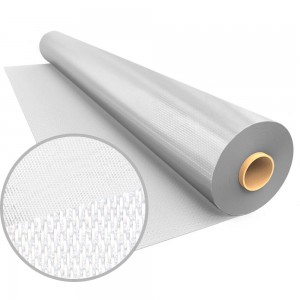

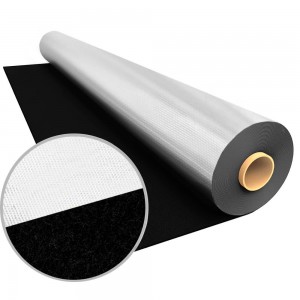

Flame retardant fabric WELS1 ALP is composed by an aluminized fiberglass base on one side and a silicone coating for high temperature on the other side of the fabric. The silicone coating repels sparks and projections of melted metals. The aluminized side, through an aluminium particle impregnation, brings protection against radiant heat. The main difference between this special aluminization system is that the fabric obtained is more flexible and lasting during movement cycles, compared to a conventional aluminization via a constant aluminium layer. Thus, WELS1 ALP is a light fabric, completely impermeable to liquids and fumes.

Aluminized fabric WELS1 ALP is designed mainly to perform as a thermal shield or a light thermal barrier, some clear examples of its applications are in high-speed doors of industrial furnaces or in vertical curtains. In addition, WELS1 ALP fabric also offers a great protection against molten metal spills, so then it is a very recommended fabric to be used as screens in high foundries and steel industries. It can be handled and folded without a deterioration nor marking of the fabric nor the aluminized side. It can withstand temperatures up to 300ºC in continuous work arriving to withstand up to 550ºC in working peaks, and its thickness is 0,5mm.

WELS1 ALP has been tested in internal laboratories with the following tests: ISO 9151 - Convective heat -, result B1, ISO 6942 - Radiant heat - C4, it also meets regulation EN ISO 15025 with an A1-A2 classification - Limited spread to flame -.

FEATURES

- Resists continuous temperatures of 300ºC and peak temperatures of 550ºC.

- Fabric thickness 0,5 mm, weight 550g/m2 and useful width of 150 cm.

- The aluminized side offers thermal insulation before radiant heat sources.

- The silicone coating repels impacts of incandescent metal splashes.

- Totally impermeable to water, oils, acids and fumes.

- Flexible fabric, easy to handle, does not fray when being cut with scissors.

- Totally opaque, suitable to protect sensible elements.

- Flexible fabric, resistant to movement cycles.

- Its fire retardant features are permanent, not decreasing with its use. It does not expire.

Data sheet

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C4

- Traction resistance

- ISO 4606 | Warp: 2400 N ±10% Weft: 2000 N ±10%

- Flame propagation

- ISO 15025 | A1 - A2

- Water penetration resistance

- EN 20811 | > 170.000 Pa

APPLICATIONS.

- Flame retardant fabric for furnace doors.

- Flexible flame retardant barrier.

- Flame retardant aluminized curtain.

- Flame retardant aluminized covering.

- Contention barrier to fumes and liquids.

- Robot covers.

- Protection screen to radiant heat sources.

SECTORS.

- Production of ceramics, plaster or clay pieces.

- Foundries and steel industries.

- Aluminized high-speed doors.

- Light welding.

- Cement industries.

USE RECOMMENDATIONS.

- Use as vertically as possible.

- Place the aluminized side exposed to the heat source.

- The silicone side is the one exposed to projections of welding works.

- Can be washed using a wet cloth, on both sides.

- Never use alcohol, solvents, or detergents to wash it (flammable rests can remain).

- It is recommended to store it always rolled on a tube to extend its useful life.