Multi-layered textile expansion joints: Wide use in cement companies and other industries.

Uses in cement companies, gas turbines in combined cycle plants, and cogeneration plants. The use of textile expansion joints is very extended on industrial spheres, being cement companies one of the sectors that use the most this type of thermal insulators, although it is also present in all those installations where processes with high temperatures or high vibrations are performed. Such as residual treatment plants, paper and cellulose production, petrochemicals, refineries, gas turbines among others.

What factors are needed to take into account when designing multi-layered expansion joints?

- A working temperature that must stand the textile joint.

- Pressure, and its variations, produced during the production process.

- Types of gases and/or fluids, and their chemical composition.

- What the ambient conditions of the working environment are.

Also known as non-metallic expansion bands or textile expansion compensators, textile expansion joints are designed in different variants, according to the type of applications. We can find in the marketplace simple expansion joints, with only a fabric of layer, as well as others tailored with multi-layered textile structures to enhance their mechanical resistances, temperature changes, or against chemical agents.

.jpg)

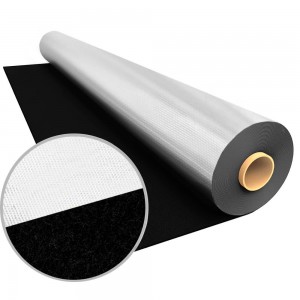

Expansion bands designed to reduce vibrations, absorb impacts, or correcting deviations between ducts, are tailored in a multi-layered textile structure way, adding different layers to condition its behavior according to the needs:

- A fabric whose external layer resists environmental conditions, or other corrosive means. In order to do that, fiberglass fabrics with PTFE and PVC coatings are used.

- In internal layers, thermal and/or waterproof insulator fabrics are used in order to minimize heat losses and avoid gases and vapors leaks that can be originated during the production process.

- In addition, technical fabrics presenting good mechanical features are considered, which also confer protection against abrasion and dimensional stability to the compensation joint itself.

The use of this kind of textile compensator is an economic solution because it helps to optimize costs and improves the energetic efficiency of cement companies. For further information about Texfire’s expansion joints, do not doubt in contacting us. Texfire has been manufacturing textile compensation joints for the cement industry within Spain for a year, gaining experience in the manufacture of this product range and opening the door to the European market in order to expand this line in other industrial branches that may demand it. . For further information about Texfire’s expansion joints, do not doubt in contacting us.