Why to use a specific welding blanket for plumbing?

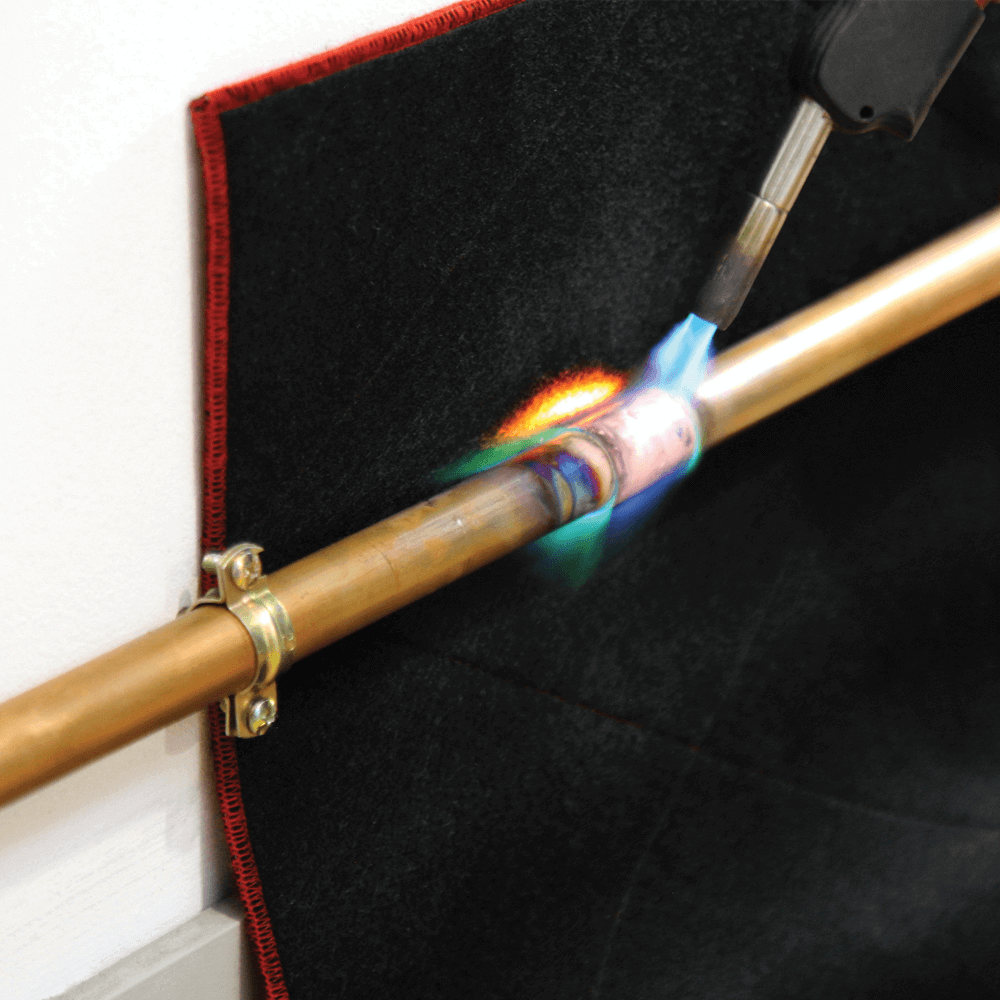

Torch welding is one of the most used procedures used in plumbing.

Torch welding is one of procedures applied to strong welding, for copper, tin, etc. and it is very used in specialized operations of union or reparation.

There are several types of torch welding:

- Manual.

- Semi-automatic.

- Automatic.

In this post, we will focus on the manual torch welding technique, that is most used in plumbing sector. We will explain the risks of this technique and the protection elements that must be used when applying this kind of welding.

Risk during the welding operation with manual torch:

The main risk lies in the operator's own welding skills, as it is the same operator who is in charge of handling the torch and positioning the pieces for joining. Furthermore, it must be taken into account that the temperature that the metal can reach during the operation will vary between 450ºC and 1500ºC, depending on the melting temperature of the metal of the pipe to be repaired or joined. Therefore, it is necessary to pay attention to all the elements in the environment as they could be damaged or cause some kind of accident.

Protective elements for manual torch welding:

- Like in all welding processes, the operator must be properly uniformed with facial mask or protective glasses against luminosity.

- Flame retardant clothing for protection against sparks and melted metal.

- Safety boots for protection against materials' impact.

- Special flame retardant gloves for welding protection.

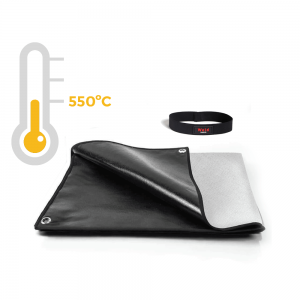

- Flame retardant welding blanket, it is the most suitable element, regarding environment protection. Many times the reparations in houses or industries are placed in areas of hard access, being very narrow places for work where the annex areas must be protected from high temperatures released by the torch. In the case of plumbing or electrical works, the most used fire blanket is commonly known as thermal blanket for plumbing.

Texfire, a manufacturer especialized in textile products for protection against heat and high temperatures, has put on the market a fire blanket especially suitable for torch welding protection. Made with a double layer of fabric Weld SX, the welding blanket for plumbing, resists peak temperatures up to 1500ºC, and it is especially flexible to adapt to the most complicated and narrow spaces where a welding job needs to be done.