Do you know the difference between heterogeneus, homogeneus and/or autogenous welding?

How is welding defined as?

As it is known, welding is defined as the union of metals by heats action, with or without other metal's contribution.

Our objective is to offer in different post some notions of the different processes and welding techniques that will help us know and educate about the risks welders and their environment are exposed and since that point know how to choose welding blankets according the fabric's composition and the risk level of the welding technique.

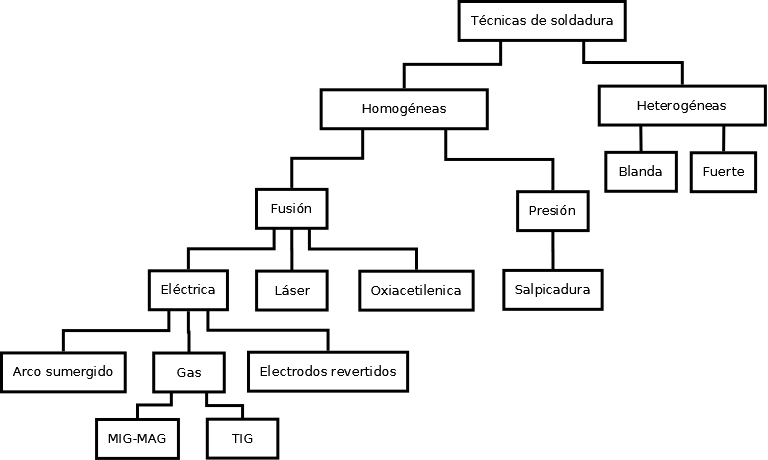

The two big groups of weld in the welding technique are:

- Heterogeneous.

- Homogeneous (or autogenous welding).

We tried to summarize each group in the welding techniques that include under their nature in the scheme we show down below.

Group 1 - Heterogeneous welding

As its name defines, materials from different or the same composition are welded and a different contribution metal is used.

In this group, there are two types:

| WELDING | TEMPERATURE | CONTRIBUTION MATERIAL |

| Soft | Under 400ºC | Mostly used tin and lead alloys |

| Strong / Hard o Yellow | From 800 ºC | Silver, copper and Zinc alloys. |

- Soft welding is used to weld cables, electric components, metal sheets

- Strong welding require a considerable resistance, or if we want to obtain joining that have to resist high efforts or excessive temperatures. A strong weld is stronger than the same metal that joins.

Group 2. Homogeneous welding (and autogenous welding)

As it names shows, the welded materials and the contribution metal are for the same composition, and achieves a better join when cold.

In the case that a contribution metal doesn't exist, homogeneous welding is called autogenous welding.

In this group there are two types:

| WELDING | Fundamental concept |

| By pressure | Apply heat to the material and when finding in plastic state, proceed to join by pressure both materials until both are joined. |

| By fusion | Apply higher degrees of temperature to the materials When melted they fuse themselves |

Texfire offers the chance to buy different types of welding blankets, custom tailored and fabric meters 1,50 meters wide starting at 3 linear meters, in addition it also develops a range of accessories for welding protection that will include:

- Welder apron.

- Bandana.

- Gaiters.

- Hoses.

- Welder pillows.

- Protective neck gaiter.

For more information, visit our online-store or contact us through our contact form.