Do you know American regulation for protection in welding?

American regulation ANSI FM 4950 establishes the essential requirements that welding pillows, welding blankets and welding curtains must meet to prevent ignition of fuels, machinery or other elements during the welding operation.

Categories

Regulation ANSI FM 4950 establish three categories with a specific acceptation criteria under its final application:

- Welding pillows: must be used horizontally, must protect the area under the place where the work is done, so they must resit melted metals, direct flames or other heat sources. The temperature of the pillow's other side mustn't be over 260 °C.

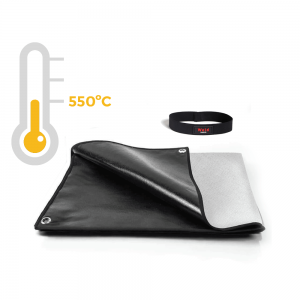

- Welding blankets: must be used horizontally, must protect closer areas to the working place from sparks, flames or heat caused by welding, besides being prepared for a less intense exposition than welding pillows, the temperature of the blanket's other side mustn't be over 260 °C.

- Welding curtains: different to the before mentioned categories, welding curtains must be placed vertically, must protect from sparks expelled from working areas, as well as melted metals. Although, the most important feature to take into account in welding curtains must be that they always have to maintain their flexibility and original dimensions.

Tests

To determine that each category meets the featured named before, 3 tests are done.

- Oxyacetylene machinery cutting test. This test is used to prove the behavior of each fabric before a welding operation of stain cut. Test pieces are placed just under the cutting area, welding blankets and welding pillows are placed horizontally and curtains vertically. Test pieces placed horizontally will have 7 temperature sensors in the non-exposed to fire surface.

- Paper ignition test. This testing method consists in placing a totally new paper in a metallic plate just under the test pieces placed horizontally during the oxyacetylene cutting test. Once finished, the paper is analyzed.

- Test to see fragility after carbonation. This test is used to verify that after oxyacetylene cutting test, the carbonized surface does not break.

These tests are done over 8 fabric samples of each category.

- 4 samples placed weft direction (horizontally).

- 4 samples placed warp direction (vertically).

Also this test will be done over 2 samples, one weft direction and the other waft direction, of each type after being exposed to UV beams exposure and water for 1000 hours, that is to say after an aging process.

Behavior

Once known the test methods, to classify each category under the protection level, the behavior before each test is specified.

- Welding pillows: During the oxyacetylene cutting test, the flame mustn't pass the fabric, the temperature of the fabric's other side mustn't be over 260 °C. With the paper ignition test, it must be verified that paper doesn't have any signs of ignition. Later on, with the test to see fragility after carbonation, it is essential that the carbonized surface doesn't break when folding the test piece. Test pieces after aging must keep the same features after being submitted to those tests.

- Welding blankets: During the oxyacetylene cutting test, the flame mustn't pass the fabric, the temperature of the fabric's other side mustn't be over 260 °C. With the paper ignition test, signs like discoloration of paper and holes of less than 25 mm diameter are permitted. Later on, with the test to see fragility after carbonation, it is essential that the carbonized surface doesn't break when folding the test piece. Any damage in the fabric caused by melted metals is excluded. Test pieces after aging must keep the same features after being submitted to those tests.

- Welding curtains: During the oxyacetylene cutting test, the flame mustn't pass the fabric, nor melt or spread the flame. Vertical position must be always flexible, leaving minimum 51 mm clearance, that is to say excess fabric resting in the inferior surface of the testing system. Test pieces after aging must keep the same features after being submitted to those tests.