Welding blanket as a protective complement in body shops

Welding blankets allow working in a more quiet and safe place in body shops

Works done in a mechanical workshop of sheet and paint are multiple and varied because it is the place where the aesthetics of vehicles is restored after any kind of accident, exposition before adverse climatic conditions...

The final goal of any mechanic is delivered the car where he has been working at in perfect conditions, in the same when as when it first when out of concessionaire.

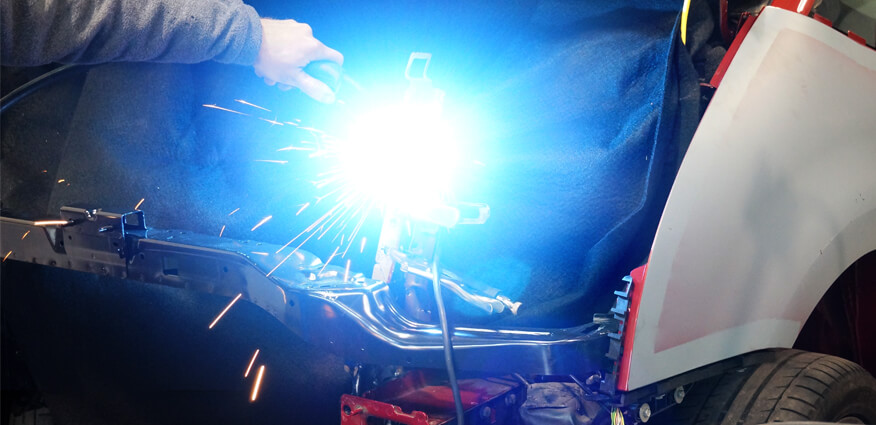

Many times, when vehicles sheets are recorded, it is necessary to use cut and welding techniques to join different pieces. Despite very aggressive techniques are not used very often, cuts made with small mole and the type of welding use to be in iron thread, aluminum and stainless steel using usually mig or arc welding techniques, if a special care is requited to not damage other vehicle's parts like:

- The engine.

- Car glasses.

- Tapestry.

The best way to protect these vehicle parts before the slags produce by cutting and welding jobs is by using a flame resistant welding blanket.

This is the reason why, every time, more mechanics use welding blankets as a protection complement during their reparation jobs. It is the quietest way to work and ensures that other parts of the vehicle are not damaged. Depending on the type of welding done, it is recommended the use of a type of blanket or other for our personal protection as well as the protection of environment and objects. As we already said, mechanical workshops don't use to apply specially aggressive welding and cutting techniques, so a welding blanket could have a long useful life in a mechanical workshop.