REGULATION FOR WELDING ISO 11611: TYPES OF RECOMMENDED WELDING ACCORDING TO ITS CLASSIFICATION

The regulation UNE EN ISO 11611 certifies the protection clothes for welding and connected techniques. To certify this regulation, those garments must be submitted to a series of laboratory test in order to check if they meet the technical specifications of this regulation. As you may see in our website, thay must meet a series of requisites.

In this post we will focus in the requisites regarding thermal features of the fabric, because these are the tests we do in Texfire laboratories.

Down below, you could observe a summary table of the thermal features regulations fom the fabric and its classification.

The fabrics of WELD range meet the classifications shown down below:

| Regulation | Description | Classificacion |

| ISO 15025 | Flame Propagation | A1 (any hole must be shaped in the test) and A2 (doesn't specifies that any hole must be shaped) |

| EN ISO 9150 | Small spashes impact | CLASS 1> 15 drops CLASS 2>25 drops |

| ISO 9151 | Radiant heat | CLASS 1: RHTI 24≥ 7 CLASS 2: RHTI 24≥ 16 |

Hereunder you could observe what fabric is recommended according to the type of welding in terms of its classification:

| Type of welder's clothes | Selection criteria related to the process: | Selection criteria related to environmental conditions: |

| CLASS 1 | Manual welding techniques with slight formation of splashes and drop, for example:

|

Machines operation, for ecample:

|

|

CLASS 2 |

|

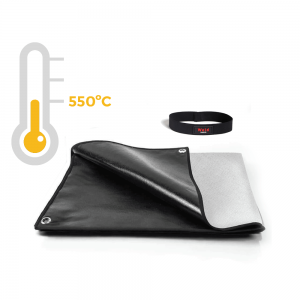

Texfire has a range of welding complements than meet this regulation.