WELDING BLANKET WELD SX

FLAME RETARDANT BLANKET FOR STRONG WELDING, HEAT INSULATOR 1300ºC

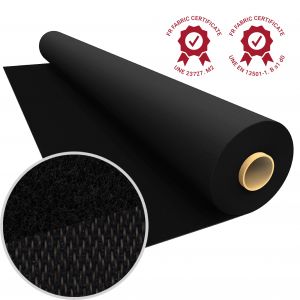

WELD SX welding blanket has been developed and manufactured solely in Texfire. Tailored with WELD SX fabric, it is the only welding blanket that can retain incandescent sparks while performing as a thermal barrier.

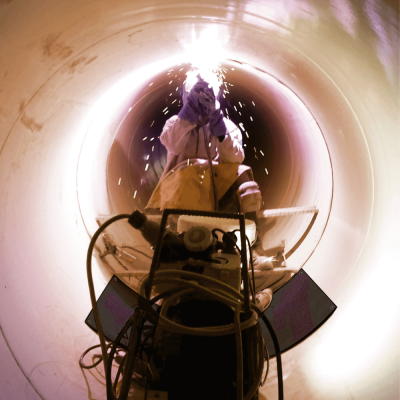

Provides protection for people, objects, surfaces, and installations against sparks and splashes resulting from most types of welding: MIG, electrode, TIG, spot welding, and other welding techniques. It is equally effective for cutting operations: radial cutting, oxy-fuel cutting, plasma cutting, and grinding...

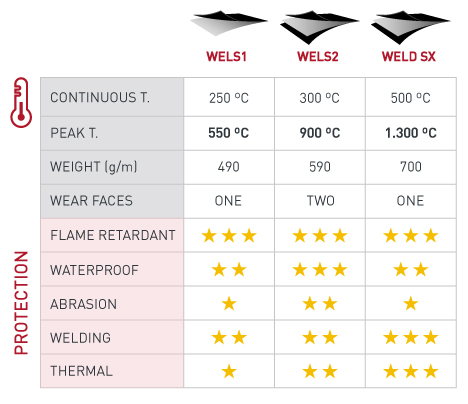

SEE WELDING FABRICS COMPARATIVE TABLE

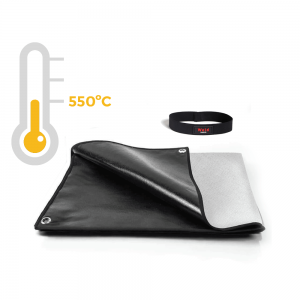

Texfire’s WELD SX welding blanket has a silicone finish for high temperatures (shiny black side) that repels incandescent sparks and fused metal splashes, avoiding that those are stuck in the fabric’s surface, not piercing nor carbonizing the surface this way, which extends its useful life significantly. PREOX mat fabric on the other side performs as a thermal barrier, avoiding notably heat transference from one side of the blanket to the other, remaining as the only blanket in the market that performs as a thermal barrier (thermal insulator) while containing incandescent projections (Flame retardant shield).

The blanket’s edge is reinforced with a black bies, and it’s tailored with meta-aramid black colored fire resistant thread. It has metallic grommets on each corner to ease its installation and it includes an elastic band to store it easily and properly.

WELD SX welding blanket can be used both vertically, diagonally and horizontally, hung or in direct contact with the surface to protect. The silicone side is placed in exposure to the sparks, and the mat side is placed in contact with the material or surface to protect and isolate from heat.

Available in two different sizes:

- 150x100 cm. (1.100 gr.)

- 200x150 cm. (2.200 gr.)

This welding blanket, created in 2019 and tested by professional welders, is being used nowadays in special and conventional welding workshops, from shipyards up to boilermaker industries, steel industries or any workshop that requires protection or spark contention up to 1.300ºC. The continuous work temperature of this blanket is around 500ºC.

The WELD SX fabric used in its construction obtained the EN ISO 13501-1 certification in 2023 - This classifies its fire behavior concerning construction products and building elements - achieving B s1 d0 ratings. Additionally, the WELD SX fabric has recently been certified (in the year 2020) under the Spanish regulation UNE 23727 - Evaluating fire reaction of construction materials, with an M2 classification.

FEATURES

- Fabric thickness: 2.1 mm.

- Repels impacts from chips, sparks, or other incandescent particles.

- The silicone-coated side is impermeable to liquids, fats, and oils.

- Lightweight and flexible, easy to handle, use, and store.

- Suitable for indoor and outdoor use.

- Completely opaque, ideal for protecting items.

- Thermal insulation.

- Textile bias finishes and made with black flame retardant meta-aramid thread.

- Includes metal grommets in each corner for easy placement.

- The WELD SX fabric is inherently fire resistant, does not burn, melt, or drip.

- Intrinsic properties in the fibers; its properties do not diminish over time.

Data sheet

- Fire resistance

- UNE 23727 | M2

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C1

- Traction resistance

- EN 13934 -1 | Warp > 2700 N, Weft > 1700 N

- Flame propagation

- ISO 15025 | A1-A2

- Melted metal splashes

- EN ISO 9185 | E3/D3

- Water penetration resistance

- EN 20811 | 100

- Resistance welding and cutting projections

- EN ISO 9150/EN 11611 | CLASS 2

- Abrasion Resistance

- ISO 12947-2 | rev > 20.000 cycles

- Fire behavior

- EN ISO 13501-1 | Results of B s1 d0

APPLICATIONS.

- Flame retardant blanket for MIG welding.

- Flame retardant blanket for TIG welding.

- Flame retardant blanket for Electrode welding.

- Flame retardant blanket for radial cutting tasks.

- Flame retardant blanket for oxycut tasks.

- Flame retardant blanket for plasma cutting tasks.

SECTORS.

- Welding Workshops.

- Automotive.

- Naval sector and shipyards.

- Construction sector and subcontractors.

- Foundries, metal and steel industries.

- Mechanics workshops.

- Machinery manufacturers.

- Boilermaking industries.

- Petrochemical and pharmaceutical sectors.

RECOMMENDATIONS.

- Always place the black silicone side in contact with incandescent projections.

- Can be washed using a wet cloth.

- Never use alcohols, solvents or detergents to wash it.

- Don’t rub, brush or vacuum the mat side.

- As longer the distance from the sparking source to the fabric, the better it will behave.

- It is recommended to store it always with the elastic band, in order to extend its useful life.

- In case of any damage to the product that may compromise its proper performance, it is recommended to replace it, to ensure maximum safety and protection.