We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Cookie preferences

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | texfire.net | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | texfire.net | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |

- HOME

- +Flame retardant fabrics

- Mineral Fiber Fabrics

- Aluminized fabric

- Coatings

- Multilayered fabric

- Nonwoven

- Welding fabric

- Thermal barrier fabric

- Thermal shield fabric

- Fabric for extreme temperatures

- Fabric for foundries

- Fabric for electric companies

- Fabric for petrochemistry

- Fabric for events and pyrotechnics

- Aramid Fabrics

- Fabrics for Mechanical Strain

- Emergency Services Fabrics

- +Flame retardant products

- +Textile lagging

- Company

- Technical videos

- Trabaja con nosotros

WELDING FABRICS COMPARATIVE TABLE

Texfire's flame retardant technical welding fabrics are designed to protect from the impacts of incandescent metal particles and to have a better resistance. To design them we have considered the risks to which welder is exposed, as well as the different types of welding and cutting, offering excellent results: UNE 23727 - M1 and EN 13773 - Class 1. Also in the tests carried out in the internal laboratories They exceed the standards: EN ISO 9185 and EN ISO 11611.

They are permanent, flexible and very resistant flame retardant fabrics. Suitable to offer the highest safety and protection against sparks, metal slag and molten metal produced during welding and cutting works and related techniques. They incorporate an advanced silicone coating that prevents incandescent particles from sticking to the fabric, protecting and extending its service life.

These fabrics are available in three protection levels: soft solder, braze, and braze + thermal insulation. The following comparative table shows its composition, characteristics, method of use and applications:

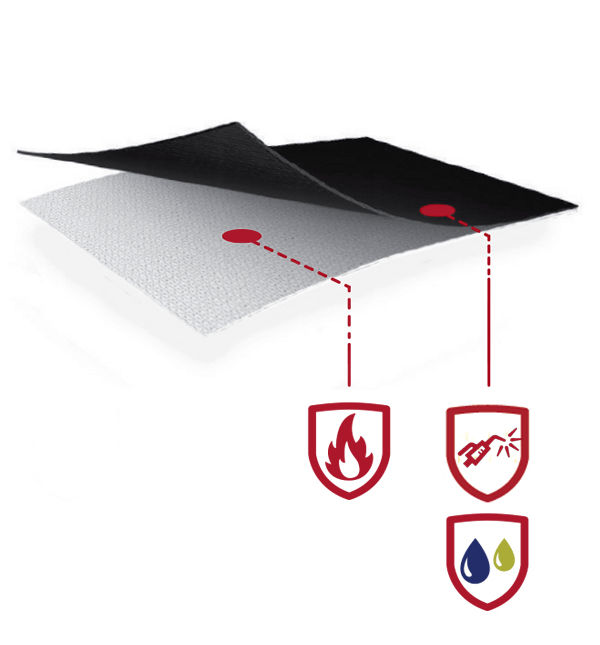

84% FV 16% SIL

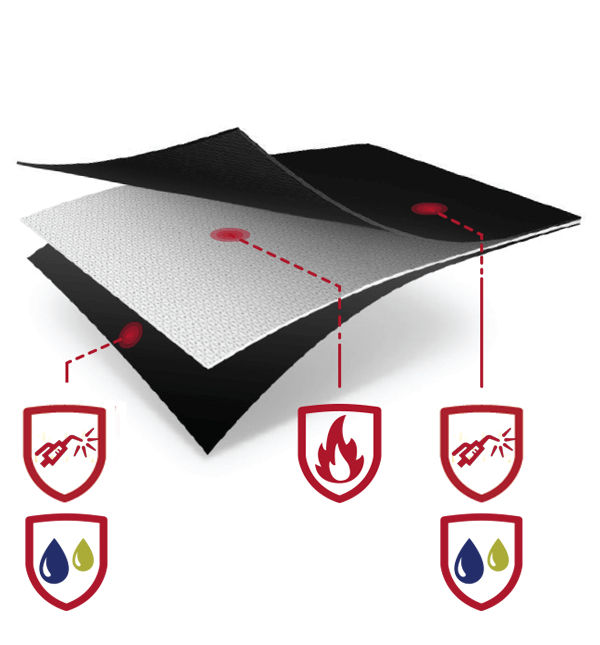

72% FV 28% SIL

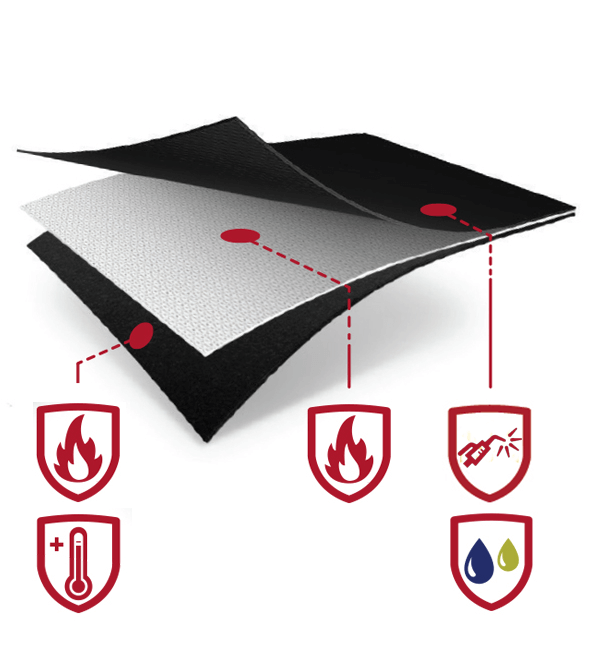

62% FV 28% PRX 10% SIL

490 gr/m² ± 5%

490 gr/m² ± 5%

490 gr/m² ± 5%

150 cm

150 cm

150 cm

Satin

Satin

Satin

Advanced recovery of black silicone on one side

Advanced recovery of black silicone in both sides

Advanced recovery of black silicone on one side and thermal barrier on the other

EN ISO 9185 / EN ISO 11611

EN ISO 9185 / EN ISO 11611

EN ISO 9185 / EN ISO 11611

UNE 23727 M1

UNE 23727 M1

EN 13773 Class 1

UNE 23727 M2

550ºC

900ºC

1300ºC

250ºC

300ºC

500ºC

100x150 and 200x150

100x150 and 200x150

100x150 and 200x150

Very flexible, one side impermeable*

Bothe sides impermeable*

One side impermeable other thermal insulator*