We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Cookie preferences

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | texfire.net | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | texfire.net | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |

- HOME

- +Flame retardant fabrics

- Mineral Fiber Fabrics

- Aluminized fabric

- Coatings

- Multilayered fabric

- Nonwoven

- Welding fabric

- Thermal barrier fabric

- Thermal shield fabric

- Fabric for extreme temperatures

- Fabric for foundries

- Fabric for electric companies

- Fabric for petrochemistry

- Fabric for events and pyrotechnics

- Aramid Fabrics

- Fabrics for Mechanical Strain

- Emergency Services Fabrics

- +Flame retardant products

- +Textile lagging

- Company

- Technical videos

- Trabaja con nosotros

ISO 9150:1988 Protective clothing - Determination of behaviour of materials on impact of small splashes of molten metal

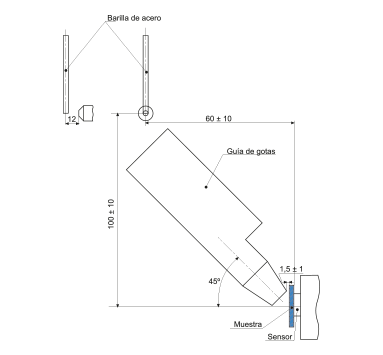

Test must be done over 10 testing sample with the size of 120 mm x 20 mm. Testing rods composition is very importante, because it affects to measures repeatability. Composition must be according ISO 636 standards and lineal density will be (0,5 + 0,2) g/cm.

A size of the steel rod is melted, in the flame of a oxycetylene torch with a 1,2mm diameter hole. Rod is taken forward by a variable speed engine with a pulley system. Before testing, the engine speed must be adjusted in order to feed the steed rod with a 10g/min speed. All the parameters once adjusted, a test is done consisting in the proyection of iron melted drops in a point over the testing sample, vertically oriented, and the number of drops needed to heat temperature to 40ºK are measured in a temperature sensor placed behind the sample.