We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Cookie preferences

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | texfire.net | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | texfire.net | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |

- HOME

- +Flame retardant fabrics

- Mineral Fiber Fabrics

- Aluminized fabric

- Coatings

- Multilayered fabric

- Nonwoven

- Welding fabric

- Thermal barrier fabric

- Thermal shield fabric

- Fabric for extreme temperatures

- Fabric for foundries

- Fabric for electric companies

- Fabric for petrochemistry

- Fabric for events and pyrotechnics

- Aramid Fabrics

- Fabrics for Mechanical Strain

- Emergency Services Fabrics

- +Flame retardant products

- +Textile lagging

- Company

- Technical videos

- Trabaja con nosotros

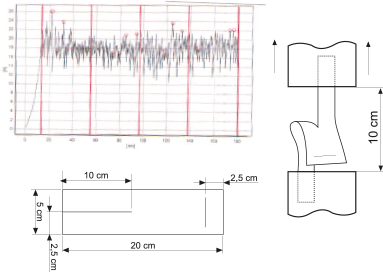

UNE-EN ISO 13937-2:2001 Textiles – Tear properties of fabrics

Five samples for the warp and five samples for the weave must be tested for each material. Test: the test piece is fixed on the clamps, with a leg on each of them. The test piece non-cut part is free. The dynamometer is turned on with a 100 mm/min constant speed, moving one of the clamps (mobile clamp) and the tearing must be continued until it arrives to the marked point 2,5 cm of the test piece's edge.

Tearing calculation: from each of the tested test pieces, the resulting graphic must be divided in four equal parts. First part must be despised and the remaining three, the two higher peaks and two lower peaks are taken. With these 12 obtained results in each testing tube a media is done.