Large format fire resistant curtains and blankets for welding

In welding, cutting, or grinding work carried out in large spaces, such as industrial halls, shipyards, or in the construction of large-scale metal structures, protection against sparks and metal projections can be a major challenge due to the high fire risk. Custom-made fire resistant curtains and blankets are effective solutions that perfectly meet the needs of large-scale projects.

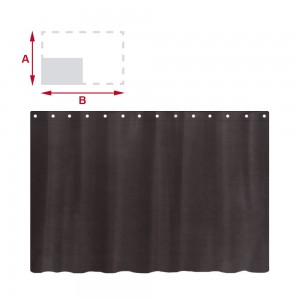

CUSTOM-MADE WELDING CURTAINS

Custom-made welding curtains are an ideal option for work where large areas need to be enclosed. For large-scale projects, such as welding in shipyards or the construction of large metal structures, Texfire can manufacture custom-made welding curtains according to the specific dimensions provided by the client, offering effective fire resistant protection.

The custom-made welding curtains are made from WelS2 fabric, a material consisting of fiberglass with a special high-temperature coating on both sides, making them suitable to withstand the high temperatures and sparks generated during welding processes. Additionally, the WelS2 fabric is waterproof, completely opaque, and protects against UV rays, making it an ideal choice for demanding industrial environments.

Certification: The custom-made welding curtains are certified according to EN ISO 11612 (protection against heat and fire) and EN 13501-1 (classification of fire reaction for building materials), ensuring their reliability and durability in industrial welding environments.

Features:

- Metal eyelets on the top and sides for fastening.

- Meta-Aramida thread or reinforced Para-Aramida thread, ensuring seam durability.

- Reinforced seams to guarantee maximum strength.

- Inherent fire resistant material, providing protection without the need for additional treatments.

More information on custom-made welding curtains here.

CUSTOM-MADE WELDING BLANKETS

Custom-made fire resistant blankets for welding allow you to cover large surfaces, equipment, or objects during the welding process. Texfire manufactures welding blankets with three types of fabrics, tailored to different types of welding, and with unique features to protect against sparks and extreme heat. Additionally, all blankets are made from inherent fire resistant materials, requiring no further priming to maintain their fire resistant properties.

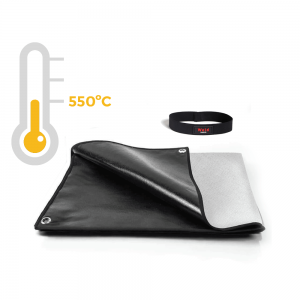

WELD S1 BLANKETS

The Weld S1 blanket is made from fire resistant WELS1 fabric, a fiberglass material with a silicone coating for high temperatures on one side. This coating prevents incandescent particles from embedding in the blanket, increasing its lifespan. It is lightweight, flexible, and waterproof, making it ideal for light welding tasks.

Certification: The WELS1 fabric is certified according to the UNE 23727 (Fire reaction of building materials), with the M1 classification.

Features:

- Temperatures: Resists 250ºC continuously and peaks up to 550ºC.

- Recommended use: Ideal for light welding, such as arc welding and TIG welding.

- Recommended position: Vertical or diagonal.

- Metal eyelets to facilitate fastening.

- Meta-Aramida thread or Para-Aramida thread reinforced in the seams.

- Reinforced seams to guarantee durability and resistance.

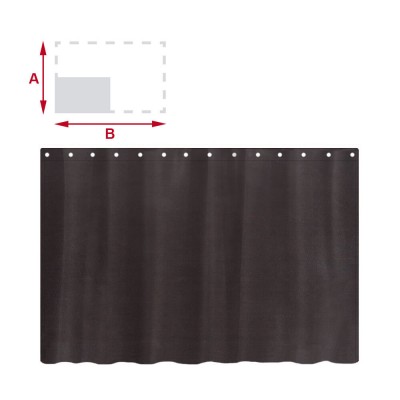

WELD S2 BLANKETS

The Weld S2 blanket is made from fire resistant WELS2 fabric, providing maximum safety and protection against sparks and metal projections. It incorporates a silicone coating on both sides, preventing projections from sticking, and allows it to be used on both sides. It is completely impermeable to liquids, oils, and grease, making it easy to clean.

Certification: The WELS2 fabric is certified according to UNE 23727 (Fire reaction of building materials, M1 classification), UNE 13773 (Fire behavior of curtains and drapes, Class 1), and EN ISO 13501-1 (A2 s1 d0).

Features:

- Temperatures: Resists 300ºC continuously and peaks up to 900ºC.

- Recommended use: Ideal for MIG welding, TIG welding, arc welding, and plasma and oxy-fuel cutting.

- Recommended position: Vertical or diagonal.

- Metal eyelets to facilitate fastening.

- Meta-Aramida thread or Para-Aramida thread reinforced in the seams.

- Reinforced seams to guarantee durability and resistance.

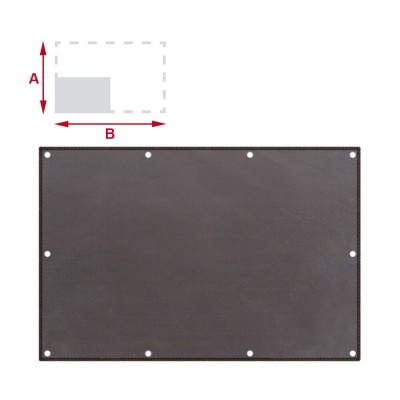

WELD SX BLANKETS

The Weld SX blanket is made from WELD SX fabric, the only material capable of containing incandescent sparks while acting as a thermal barrier. Its construction includes silicone on one side and a Preox fabric on the other, providing thermal insulation while limiting heat transfer. This blanket is ideal for high-performance welding and withstands continuous working temperatures of 500ºC and thermal peaks up to 1300ºC.

Certification: The WELD SX fabric is certified according to EN ISO 13501-1 (Fire behavior classification for building products, B s1 d0) and UNE 23727 (Fire reaction of building materials, M2 classification).

Features:

- Temperatures: Resists 500ºC continuously and peaks up to 1300ºC.

- Recommended use: Ideal for MIG welding, TIG welding, electrode welding, spot welding, radial cutting, oxy-fuel cutting, plasma cutting, and grinding.

- Recommended position: Vertical or diagonal.

- Metal eyelets to facilitate fastening.

- Meta-Aramida thread or Para-Aramida thread reinforced in the seams.

- Reinforced seams to guarantee durability and resistance.

More information on welding blankets here.

For more information about custom-made welding blankets or curtains specific to your project, feel free to contact the Texfire technical team.