Click for more products.

No produts were found.

0

Shopping cartYour shopping cart is empty.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Cookie preferences

Functional cookies

Technical

No

Yes

Description and cookies

Functional cookies are strictly necessary to provide the services of the shop, as well as for its proper functioning, so it is not possible to refuse their use. They allow the user to browse through our website and use the different options or services that exist on it.

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | texfire.net | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | texfire.net | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |

Advertising Cookies

No

Yes

Description

These are cookies that collect information about the advertisements shown to users of the website. They can be anonymous, if they only collect information about the advertising spaces shown without identifying the user, or personalised, if they collect personal information about the user of the shop by a third party, for the personalisation of these advertising spaces.

Analytics cookies

No

Yes

Description

Collect information about the user's browsing experience in the shop, usually anonymously, although sometimes they also allow the user to be uniquely and unequivocally identified in order to obtain reports on the user's interests in the products or services offered by the shop.

Performance cookies

No

Yes

Description

These are used to improve the browsing experience and optimize the operation of the shop.

Other cookies

No

Yes

Description

These are cookies without a clear purpose or those that we are still in the process of classifying.

Menu

- HOME

- +Flame retardant fabrics

- Mineral Fiber Fabrics

- Aluminized fabric

- Coatings

- Multilayered fabric

- Nonwoven

- Welding fabric

- Thermal barrier fabric

- Thermal shield fabric

- Fabric for extreme temperatures

- Fabric for foundries

- Fabric for electric companies

- Fabric for petrochemistry

- Fabric for events and pyrotechnics

- Aramid Fabrics

- Fabrics for Mechanical Strain

- Emergency Services Fabrics

- +Flame retardant products

- +Textile lagging

- Company

- Technical videos

- Trabaja con nosotros

ALUMINIZED FABRIC SAMPLES

Ref:

41-040

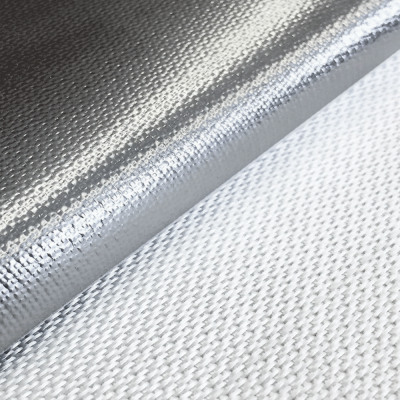

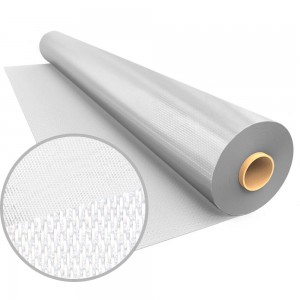

Different flame retardant fabric compositions are used as the base for aluminised fabrics, depending on the final application of the laminate: thermal barriers, gaiters for steelmaking, furnace curtains—these are some real examples of applications of Texfire’s aluminised fabrics. The available samples measure 15x1x21 cm. The aluminised fabrics we can find are as follows:

- Aluminised fabric EGLA 200 AL: This is an E-glass fibreglass fabric weighing 200 gsm with a 12-micron aluminium film. Its aluminised side acts as a thermal shield, blocking radiant heat and improving insulation against convective heat or flames. It offers dimensional stability, as well as mechanical and thermal resistance, withstanding continuous temperatures of up to 450ºC and peaks of 550ºC.

- Aluminised fabric EGLA 430 AL: This is a fire resistant fibreglass material with a 12-micron aluminised layer. It has a thickness of 0.4 mm, a total weight of 450 g/m², and withstands continuous temperatures of 450°C and peaks of 550°C. Its aluminised layer acts as a thermal shield, offering protection against radiant heat and direct flame contact.

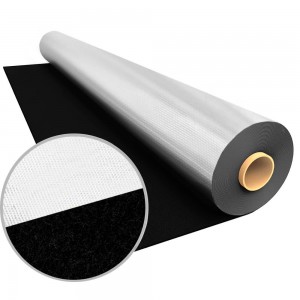

- Aluminised fabric WELS1 ALP: It combines aluminised fibreglass on one side, impregnated with aluminium particles, and a high-temperature-resistant silicone coating on the other. The silicone repels sparks and molten metals, while the aluminised side protects against radiant heat. This special design provides greater flexibility and durability compared to conventional aluminising. Furthermore, it is lightweight and impervious to liquids and fumes.

- Aluminised nonwoven nt preox 500AL: This is a nonwoven made of pre-carbonised polyacrylonitrile (PPAN) fibres, with a 12-micron aluminium layer. Preox fibres provide high fire resistance and excellent thermal insulation, with a LOI index close to 40. The aluminised side acts as a thermal shield against convective and radiant heat or flames. It has a thickness of 4.5 mm, a weight of 500 g/m², and offers great flexibility and adaptability.

- Aluminised fabric paratex 460 ALP: Composed of para-aramid fibres with a herringbone weave, it provides flexibility and inherent fire resistance. Its powdered aluminium layer maintains the fabric’s adaptability and prevents cracks or delamination. It is resistant to abrasion, cutting, vibrations, and temperatures of up to 400°C. The aluminised side serves as a thermal shield against radiant and convective heat, and also protects against UV rays.

- Aluminised thermal shield fabric altox 450: It is fire resistant and acts as a thermal shield against flames and high temperatures. It combines aluminised fibreglass on one side with a layer of NT Preox 200 nonwoven, which enhances thermal insulation and bolsters its function as a thermal barrier. Its multi-layer design makes it especially effective in protecting against extreme heat and direct flame sources.

- High-temperature fabric silica 180 AL2: This is an aluminised fire resistant fabric on both sides, designed to withstand extreme heat. Its core, made of mineral fibres with 95% silica, grants it high thermal resistance, allowing it to maintain its structural integrity at temperatures of up to 850°C.

- High-temperature fabric silica 300 AL: It withstands continuous temperatures of up to 850°C without losing its structural integrity. It incorporates a 12-micron aluminium foil on one of its sides, providing additional protection.

Related products