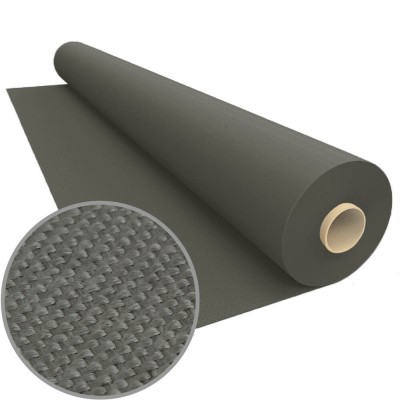

REINFORCED FR FABRIC EGLA 1200IN

FLAME RETARDANT FABRIC FOR HIGH TEMPERATURES REINFORCED WITH STEEL

EGLA 1200IN is a flame retardant fabric made of texturized fiberglass with a stainless steel filament armouring that increases its mechanical resistance and blocks the passage of flames, raising the fabric’s stability and integrity in continued high temperature works. In addition, it has a treatment made of an inorganic formula on both sides, tha brings the fibers together and improves its duration to vibrations. This treatment enhances the lifespan of the fabric same as eases its handling and cut, also raising the resistance to high temperatures. It is an inherent fire resistant fabric, which ensures its features during all its lifespan.

EGLA 1200IN flame retardant fabric has been developed for applications with sustained high temperatures of 700ºC in continuous and peak temperatures up to 800ºC, without a decline of its flexibility or mechanical features. Thanks to its great resistance to abrasion and vibrations, it is used as a fabric of the hot side, for the production of cases and leggings of motors, dilatation strips, expansion joins, parts on vibration, etc. Its structure reinforced with stainless steel ensures the dimensional stability even in extreme situations, for example, in a direct contact with a flame or situations where fiberglass fibers have lost part of their dimensional stability.

EGLA 1200IN fabric has been tested in Texfire’s internal laboratories, with regulation ISO 15025 - Protection against flames. Test method for limited flame propagation - with an A1-A2 result. Also, it resists up to 8.000 abrasion cycles according to test ISO 12947-2 - Determination of abrasion resistance of fabrics by the Martindale method.

FEATURES

- Resists continuous temperatures of 700ºC and peak temperatures up to 800ºC.

- Fabric thickness 1,4 mm, weight 1,200 g/m2 and useful wide of 150 cm.

- Resistant to abrasion and rubbing. Not easily pierced. Long lifespan.

- Available only in light grey.

- Inherent fire resistant fabric, the steel structure ensures its integrity up to 1.500ºC in border cases.

- Textured fabric, fibers with higher volume, providing more thickness to the fabric.

- Fabric for high temperatures, it resists contact heat.

- Resistant to vibrations.

- Reversible fabric (same features on both sides.)

- When in contact with flames, it causes little smoke.

Data sheet

- Traction resistance

- EN 13934-1 | Warp 3000 N ±10% Weft 1500 N ±10%

- Flame propagation

- ISO 15025 | A1 - A2

- Abrasion Resistance

- ISO 12947-2 | 8000

APPLICATIONS

- Thermal cases.

- Drapes.

- Thermal mats.

- Laggings.

- Expansion or compensation strips.

- Expansion joins.

- Motor cases.

- Battery cases.

- Cases for areas in vibration or movement.

- Coating of hot parts or areas up to 700ºC.

SECTORS

- Construction.

- Cement plants.

- Installer companies.

- Maintenance.

- Petrochemical industry.

- Boilermaking industry.