SAMPLES OF COATED FABRICS

Ref:

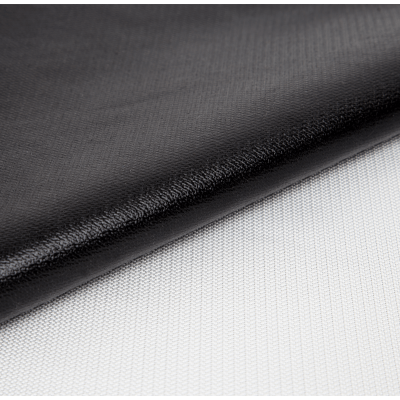

41-007

Texfire’s coated fabrics (coatings) are manufactured from a flame retardant textile base, to which a coating is applied in order to enhance or increase technical and functional properties. The coatings can be applied to one or both sides of the fabric. Texfire works with different types of coatings depending on the final application. The available samples measure 15x1x21 cm. The coated fabrics we can find are:

- FLAME-RETARDANT WELDING FABRIC WELS 1: Made with E-Glass fibreglass and a black silicone coating, it repels sparks, splashes, and is impermeable to liquids, gases, and fumes. Its fire resistant properties are permanent, withstanding continuous temperatures of 250°C and up to 550°C at peak, and its fibreglass base ensures high mechanical strength.

- FLAME-RETARDANT WELDING FABRIC WELS 2: Designed by Texfire, it withstands continuous temperatures of 300°C and peaks of 900°C. Manufactured with fibreglass, it offers mechanical strength and flexibility. Its double silicone coating repels sparks and molten metals, is impermeable to liquids and fumes, and can be used on both sides.

- FLAME-RETARDANT WELDING FABRIC WELS2 GREY: A fire resistant fibreglass fabric with a grey silicone coating on both sides, resistant to continuous temperatures of 300°C and peaks of 900°C. It repels sparks, molten metal splashes, is impermeable to liquids and fumes, flexible, mechanically strong, and can be used on both sides.

- REINFORCED FLAME-RETARDANT FABRIC WELP2 660IN: Composed of fibreglass reinforced with steel filaments and coated on both sides with a high-temperature polymer containing aluminium particles. It offers high mechanical strength after fire exposure and is impermeable to liquids, acids, and fumes.

- NNON-STICK FABRIC EGLA 100 PTFE: It combines a 110 g/m² fibreglass with a 70 g/m² PTFE coating on both sides. It is reversible, waterproof, chemically resistant to acids and corrosive liquids, non-stick, and repels substances. It endures continuous temperatures up to 260°C, providing dimensional stability and mechanical strength.

- REINFORCED FLAME-RETARDANT FABRIC EGLA 1200IN: This fire resistant fabric is made of texturised fibreglass with stainless steel filaments, improving mechanical strength and stability at high temperatures. Its inorganic treatment enhances cohesion, abrasion resistance, and vibration resistance, extending its service life and guaranteeing its inherent fire resistant properties.

- HIGH TEMPERATURE FABRIC EGLA 1000V: Manufactured with thick E-Glass fiberglass and coated with vermiculite, it withstands temperatures up to 600°C continuously. Its treatment enhances abrasion resistance and mechanical properties, providing dimensional stability and a longer lifespan. It is ideal for applications requiring high thermal and mechanical resistance in high-temperature environments.

- EXTREME HIGH-TEMPERATURE FABRIC SILICE 700V: Composed of silica fibres, withstanding continuous temperatures up to 1000°C and peaks of 1300°C. Its vermiculite coating enhances abrasion resistance, mechanical properties, dimensional stability, and service life. In addition, it provides thermal and acoustic insulation, making it ideal for high-temperature environments.

- EXTREME TEMPERATURE FABRIC SILICA P2: Manufactured with silica fibres, it withstands extreme temperatures of up to 1100°C continuously and 1500°C at peak. A polymer coating on both sides improves its abrasion resistance and makes it impermeable to liquids, fumes, and gases, making it ideal for highly demanding thermal environments.