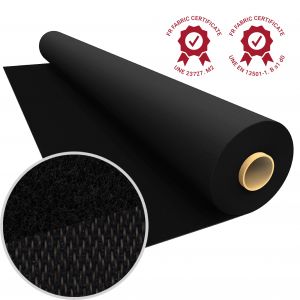

MARLAN 365 FABRIC

FLAME RETARDANT FABRIC FOR SPLASHES OF FUSING METALS

MARLAN 365, is a permanent flame retardant technical fabric, especially designed to offer protection before big aluminium or cryolite splashes as well as splashes of iron, steel, and many other fusing metals, like copper, magnesium, tin or nickel, meeting different European regulations of protection against electric arc, welding, fire and flames. Its flame retardant fibre composition make that fused metals slide through the fabric’s surface, avoiding them to get adhered causing high degree burns on skin.

The protection MARLAN 365 offers is inherent, meaning that the degree of protection does not decrease with the use of the fabric. Even if submitted to many washing cycles, its features remain unaltered during its useful life.

In addition, it as a soft and pleasing touch, with great breathability and offers a high level of comfort. For this reason It is widely used in the tailoring of personal protection equipments (PPEs) jackets and trousers, in metal foundries and steel sector, protecting in environments like: melting furnances, casting lines, rolling mills, electrolytic vats, etc.

MARLAN 365 fabric weights 365 g/m2 and has a useful wide of 157 cm. Available in marine blue. For minimum orders of 300 m, a color study can be performe, offering the fabric on a customized color.

It obtains results of 9,4 Cal/cm² regarding electric arc protection acording to American regulation ASTM F1959/F and it obtains a Class 1 result according to European regulation EN 61482-1-2 - Protection clothes against thermal hazards of an electric arc. It obtains the higher valorations on the matter of protection against aluminium D3 splashes, and against iron and steel E3 splashes, according to European regulation EN ISO 9185 - Evaluation of material’s resistance to melted metal splashes. It also meets IPAI test of Cryolite, required by foundries of primary aluminium. In addition, it meets regulation EN 11611 - Protection clothes used during welding and attached activities, obtaining a Class 1 classification. Plus, it passes EN 1149-3 - Electrostatic features.

FEATURES

- Grammage of the fabric 365 g/m² ± 5% and useful wide of 157 cm, cross twill 3/1.

- It repels the impact of incandescent splashes of fusing metals. (aluminium, Cryolite, copper, nickel, zinc, tin, magnesium, and other ferrous materials).

- Technical flame retardant fabric designed to tailor PPEs (personal protection equipments).

- Suitable to tailor jackets and trousers.

- Light, flexible and easy to use fabric, it does not tear when being cut with scissors.

- Soft and pleasing touch, with great breathability and comfort.

- Its fire resistant features are permanent, they do not decrease with use or washes. It does not expire.

- Composition: 100% MARLAN.

APPLICATIONS.

- Flame retardant fabric to tailor flame retardant jackets.

- Flame retardant fabric to tailor flame retardant trousers.

- Tejido técnico para confeccionar EPIS.

- Technical fabric to talor PPEs.

- Fabric to protect in front of fusing metals.

- Fabric that repels melted metals.

- Flame retardant fabric for steel industries.

SECTORS.

- Foundries and metal industries.

- Copper foundries.

- Aluminium foundries.

- Zinc foundries.

- Glass foundries.

- Steel industries.