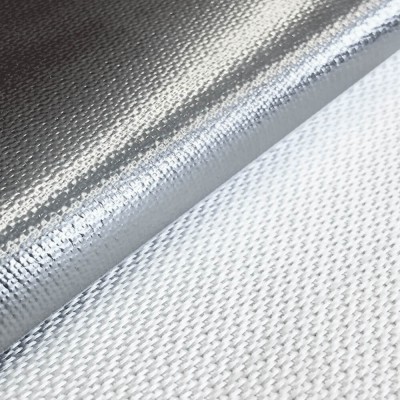

ALUMINIZED FABRIC EGLA 430 AL

ALUMINIZED FIBERGLASS FABRIC, THERMAL SHIELD.

EGLA 430 AL fabric is a flame retardant fiberglass fabric with an aluminized side. The fiberglass basis is from type E-Glass, with a thickness of 0,4 mm and a grammage of 470 gr/m2 and resists continuous work temperatures of 470ºC and peak temperatures up to 550ºC. The aluminized side conferes the features of thermal shield, protection before radiant heat sources and to a direct contact with flames to this fabric.

Thanks to its capability of thermal reflection, flame retardant fabric EGLA 430 AL can delimit areas with high temperatures by way of a curtain, for instance, in foundries. It is also suitable to use as a thermal protector or a fire resistant quilt, to delimit areas or cover objects that are sensitive to heat, high temperatures, fused metal splashes or even to isolate from fumes and gases.

Thanks to its good resistance with direct contact with flames, it is also an effective solution as an opaque curtain and even oven doors. Besides its features before fire, this is not a fabric that Texfire recommends for welding works.

This fabric has been tested in Texfire’s internal laboratories according to regulation UNE-EN ISO 15025 - Test method for limited flame spread – obtaining an A1-A2 classification. Regarding to performed tests of radiant and convective heat, it obtained a B1 result according to ISO 9151 - Determination of heat transmission when exposed to a flame. - and a C4 result according to ISO 6942 - Evaluation of materials and sets of materials when exposed to a radiant heat source.

FEATURES

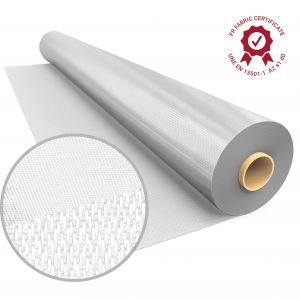

- Fabric’s thickness 0,4 mm, 470 g/m2, useful width 150 cm.

- Resists continuous temperatures of 450ºC in continuous works and 550ºC in working peaks.

- Fiberglass fiber with an aluminium sheet of 12 microns.

- Waterproof to water, oil and fumes.

- Effective thermal shield.

- Resists direct contact with flames.

Data sheet

- Convective heat

- ISO 9151 | B1

- Radiant heat

- ISO 6942 | C4

- Traction resistance

- ISO 4606 | Warp: 2400 N ±10% Weft: 2000 N ±10%

- Flame propagation

- ISO 15025 | A1 - A2

- Water penetration resistance

- EN 20811 | > 170.000 Pa

APPLICATIONS.

- Flame retardant quilt.

- Thermal protector.

- Thermal shield.

- Aluminized cases.

- Flame retardant curtain.

- Barrier against fire.

SECTORS.

- Cement industries.

- Construction.

- Naval industries.

- Large combustion plants.

- Engineering industries.

- Boilermaking industries.

- Foundries.

USE RECOMMENDATIONS.

- Use the aluminized side in front of the heat source.

- Never use alcohol, solvents or detergents to clean it, flammable remains can remain.

- A wet cloth can be used to clean the aluminized side.

- Check its status before its use.

- Do not submit the aluminized side to abrasion, rubbing or shearing forces.

- It is recommended to store it always rolled as a tube in order to extend its useful life.

- It is recommended to handle the fabric with gloves to avoid the fiberglass fibers to get in direct contact with skin,because it can cause itching.